UV Spot Curing System

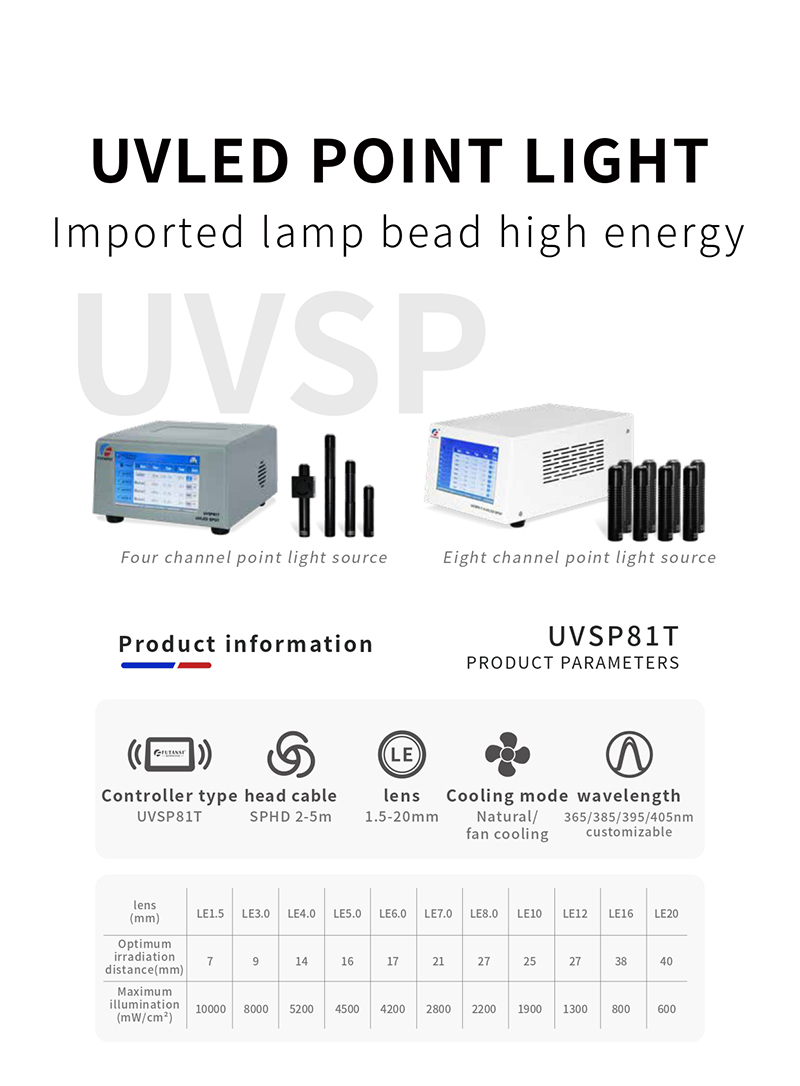

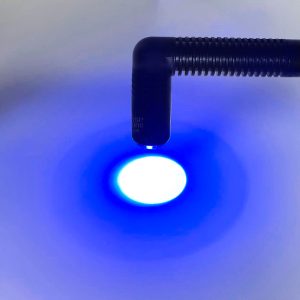

uv led spot curing systems- Wavelength365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

- Lens diameter∅1.5/2/3/4/5/6/7/8/10/12/15/18/20mm

- Cooling methodFans / Nature

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of UV spot curing system

UV spot curing system is a device that uses ultraviolet light-emitting diodes (UV LEDs) to generate high-intensity ultraviolet light. Compared with traditional UV light sources such as mercury lamps, UV LED spot curing system have higher efficiency and longer service life.UV spot curing system emit light through semiconductor materials, and are able to generate UV light in a specific wavelength range (usually 200-400nm). This UV curing spot light has a wide range of applications in industrial, medical, and scientific fields.

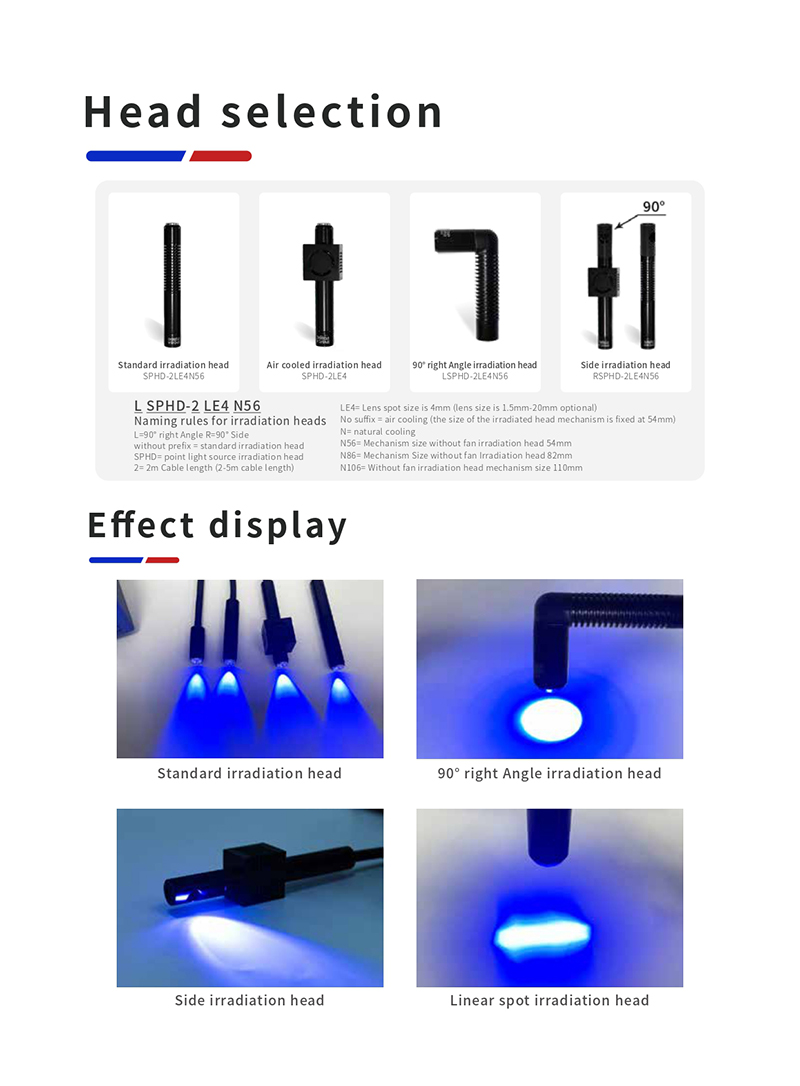

The core components of UV LED Spot curing systems include UV LED chip, optical lens, heat dissipation system and driving circuit.UV LED chip is the core of the light source, which determines the wavelength and intensity of the light source. The optical lens is used to focus and guide the UV light, ensuring the uniformity and direction of the light. The heat dissipation system ensures that the temperature of the UV LED chip is stable during operation, prolonging the service life of the device. The driver circuit provides stable current and voltage to ensure the normal operation of the light source.

Product Applications

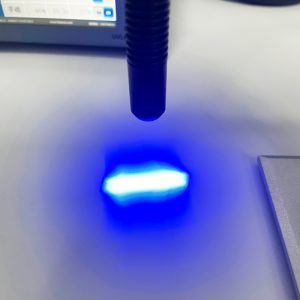

Futansi UV curing spot light is mainly used for UV adhesive, UV ink, UV varnish, UV paint, UV coating and other light-sensitive materials curing role, so that its surface glossy and bright, with good weather resistance, waterproof, friction resistance, acid and alkali resistance and other high-strength protection role. UV led light source application areas are wide, mostly used in ink printing, industrial products fixed, specific applications can refer to the following:

Industrial Manufacturing: UV spot curing system are widely used for curing, bonding and surface treatment in industrial manufacturing processes. For example, in the process of encapsulation and protection of electronic components, led spot curing system can quickly cure the glue, improve production efficiency and product quality.

Printing industry: UV spot curing system is widely used in the printing industry, especially in the curing process of UV ink. It can provide high-quality printing effect and fast drying, suitable for high-speed printing.

Medical field: In the medical field, UV spot curing system is used for disinfection and sterilisation. It can effectively kill bacteria and viruses and provide a sterile environment. In addition, UV spot curing system is also used in phototherapy and dermatological treatment, with significant therapeutic effects.

Scientific research experiment: In scientific research experiments, UV spot curing system is used for photochemical reaction and spectral analysis. It can provide a stable UV light source to ensure the accuracy and repeatability of the experimental results.

Water treatment: UV spot curing system is used for sterilisation and disinfection in water treatment process. It can effectively remove bacteria and viruses in water and provide safe drinking water.

Product Advantages

Energy efficient: UV LED spot curing system are several times more energy efficient than traditional mercury lamps, producing high intensity UV light at lower power consumption. This not only reduces energy consumption, but also reduces operating costs.

Environmentally friendly and non-polluting: UV spot systems does not contain mercury and other harmful substances, and will not produce harmful gases and wastewater, in line with environmental requirements. In addition, the disposal of UV curing systems is easier and safer.

Long life: LED spot curing light’s service life is usually more than tens of thousands of hours, far more than traditional mercury lamps. This reduces replacement frequency and maintenance costs, and improves equipment reliability and stability.

Fast start-up: UV spot cure systems are able to reach full power output instantly without warm-up time. This is especially important for applications that require a quick response, such as industrial production lines and medical equipment.

Precise control: The output intensity and wavelength of UV spot curing systems can be precisely adjusted by electronic control to suit different application requirements. This flexibility allows it to excel in a variety of complex applications.

Industry status and prospects

At present, the UV LED curing system industry is in a rapid development stage. With the continuous progress of technology and the increase of market demand, the application scope of UV LED curing systems is expanding. Especially in the context of increasingly stringent environmental protection requirements, the environmental advantages of UV LED curing systems source make it widely concerned in various fields.

In the field of industrial manufacturing, UV LED curing system’s energy efficient and long life characteristics make it an ideal alternative to traditional mercury lamps. More and more enterprises are adopting UV LED curing systems to improve production efficiency and product quality. In the printing industry, UV LED curing system’s fast curing and high-quality printing results make it the preferred light source for UV ink curing.

In the medical field, UV LED curing system has significant disinfection and sterilisation effects, and is widely used in hospitals, laboratories and home disinfection equipment. In addition, the application of UV LED curing systems in phototherapy and dermatological treatment is also expanding, with a broad market prospect.

In scientific research experiments, the stability and precise control characteristics of UV LED curing systems make it an ideal light source for photochemical reactions and spectral analysis. With the increasing demand for scientific research, the market demand for UV LED curing system is also growing.

Overall, the UV LED curing industry has a broad outlook and huge market potential. With the continuous progress of technology and the continuous expansion of the scope of application, UV LED curing system will play an important role in more fields. Enterprises should seize the opportunity to increase technological research and development efforts, and constantly improve product performance and quality to meet the diverse needs of the market.

Top 10 Manufacturers of UV Curing Ovens

Heraeus: Heraeus is a German company specialising in the development and production of high performance UV curing equipment.

Nordson: Nordson is an American company that provides UV curing equipment for a variety of industrial applications.

IST Metz: IST Metz is a German company specialising in the innovation and application of UV curing technology.

Phoseon Technology: Phoseon Technology is a U.S. company that provides high performance UV LED curing equipment.

GEW: GEW is a UK company specialising in the development and manufacture of UV curing systems.

Excelitas Technologies: Excelitas Technologies is a leading global provider of photovoltaic solutions, offering highly efficient UV curing equipment.

Futansi: Futansi is the world’s leading manufacturer of UV curing equipment, providing efficient and energy-saving UV curing solutions.

Ushio: Ushio is a Japanese company offering UV curing equipment for various industrial applications.

Dymax: Dymax is a US company specialising in the development and manufacture of UV curing adhesives and equipment.

Panasonic: Panasonic is a Japanese company that provides high performance UV curing equipment for a wide range of applications such as electronics manufacturing and automotive manufacturing.

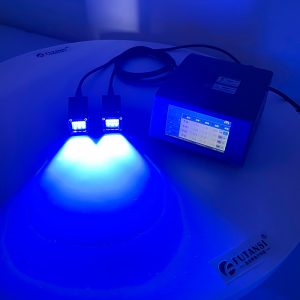

| NO. | Parts | Items | Technique Data |

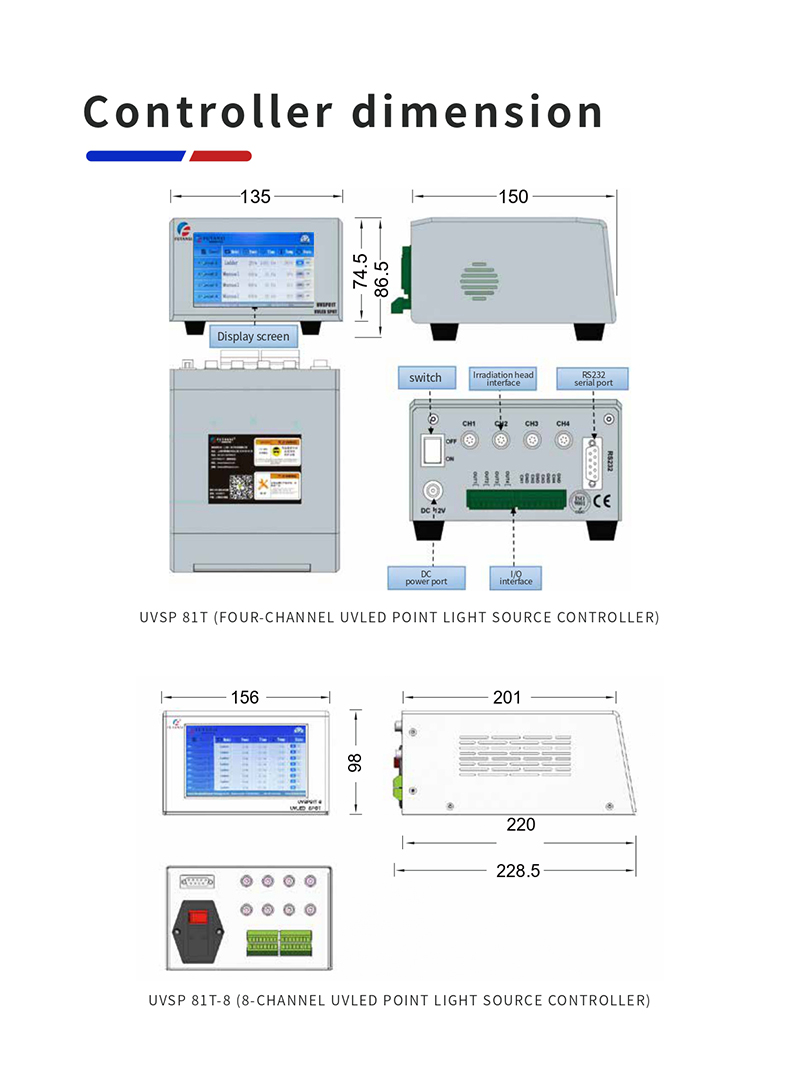

| 1 | ControlleUVSP81T | Adapter power | 12V/5A |

| 2 | MODEL SIZE | 135×86.5×150(mm) | |

| 3 | Cooling mode | Air-Cooled | |

| 4 | Control Method | On-screen touch/pedal /RS232/485 communication | |

| 5 | Adjustable range of irradiation power | 10%-100% adjustable | |

| 6 | irradiation swelling model | Manual: Steady on after startup | |

| 7 | Automatic: Set irradiation countdown time (0.1-999.9s) | ||

| 8 | Step: Achieve step irradiation (1-20 steps) | ||

| 9 | Loop ladder: single/infinite | ||

| 10 | traffic control | RS232 serial port, 485: data read and write, LED switch and parameter control | |

| 11 | I\O interface LED switch control and running state output | ||

| 12 | Irradiation headSPHD-2LE6 | heat-dissipating method | air cooling |

| 13 | Illumination head material | aluminum alloy | |

| 14 | wavelength coverage | 365±5nm | |

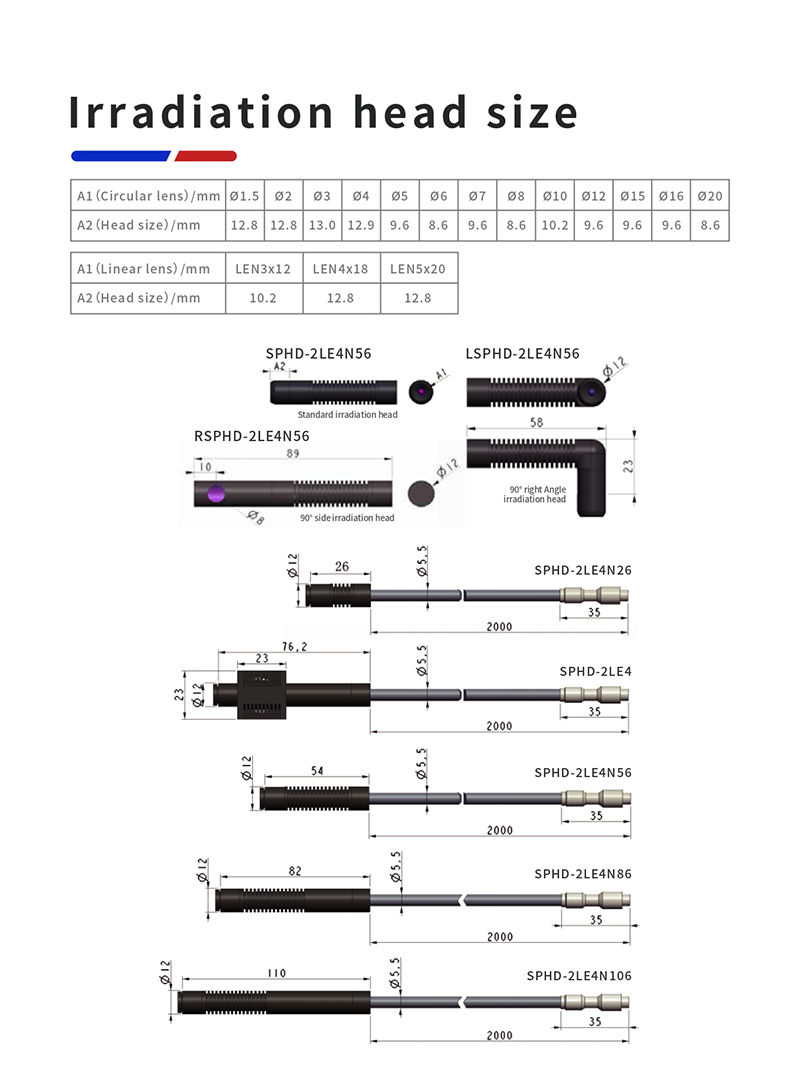

| 15 | External structural dimension | Refer to the diagram | |

| 16 | Light point size | Ø6mm | |

| 17 | Suggested range | 17 (mm) | |

| 18 | exposure intensity (MAX) | 4200 mw/c㎡(FTIU500 Illuminometer measurement data) | |

| 19 | Weight | 0.2kg | |

| 20 | Consumption power (single irradiation head) | 5W | |

| 21 | power cord | cable | 2m |

| 22 | connecting line | cable | 2m |

| 23 | electric power | Total electrical power of each component | 20w |

| 24 | Optional functions | on-line monitoring | None |

| 25 | Optional functions | Abnormal alarm of temperature and lamp bead necrosis | None |

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

韵色-300x300.jpg)