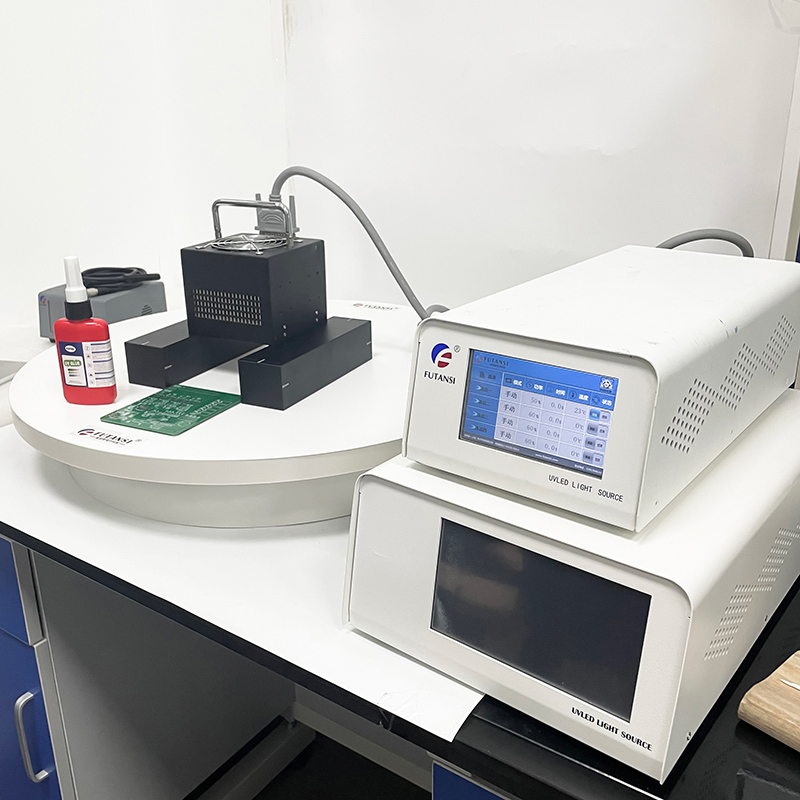

Futansi new developed three-sided illumination LED UV oven

1093three-sided illumination LED UV oven, with 3 large size UV LED light source, high power intensity, suitable for laboratory

View detailsSearch the whole station

With the wide application of UVLED light source, especially in the field of electronic devices and communication equipments, this article will discuss the principle of UVLED light source in LCD sealant curing as well as the related basic knowledge.

1. Principle of LCD sealant curing

In UV light curing, a light stabilizer or initiator needs to be added to a specific formulation of epoxy resin. When the UV coating is exposed to a certain wavelength of ultraviolet radiation, it will absorb the high-intensity UV light in the UVLED curing equipment, triggering chemical changes. At this point, the photoinitiator reacts with free radicals or ions in the coating, and these reactions lead to cross-linking of the double bonds in the prepolymer or unsaturated monomer to form monomer groups. As a result, UV coatings can be transformed from a liquid to a solid in a matter of seconds. This process is known as UVLED light source curing. However, the process is not completely finished and post-curing is still required, so the quality of the cured product needs to be checked within 5 minutes after curing.

2. UVLED light source in the LCD sealing adhesive curing application

UVLED light source has the following advantages and application value in LCD sealant curing:

Fast curing: UVLED light source provides high-intensity ultraviolet rays, which can make the sealing adhesive curing in an instant, greatly reducing the curing time and improving production efficiency.

Uniform curing: the uniform irradiation of UVLED light source can ensure that the sealant in the entire coating area to get uniform curing, to avoid the problem of non-curing or curing is not enough to improve product quality and stability.

Energy saving and environmental protection: compared with the traditional mercury lamp, UVLED light source does not contain harmful substances such as mercury, and can save energy consumption, in line with environmental requirements, for enterprises with significant energy saving and emission reduction effect.

Low maintenance cost: Because UVLED light source has a long life and is not affected by the number of switching times, there is almost no additional maintenance cost in the use of the process, which can save money for the enterprise.

3. Advantages of FUTANSI electronic technology

Through the application of UVLED light source, the curing process of LCD sealant can be more efficient, uniform and in line with the environmental requirements. If you have further questions or needs about the application of UVLED light source in LCD sealant curing, please feel free to contact us.

three-sided illumination LED UV oven, with 3 large size UV LED light source, high power intensity, suitable for laboratory

View detailsLED UV curing systems can generate heat during the curing process. To maintain optimal curing conditions and prevent overheating, a fan cooling or water chiller is employed to control the temperature of the LED lamps.

View detailsThe fully automatic nitrogen-filled UV wafer ungluer is a device that uses UV radiation and nitrogen to quickly break down the glue and remove it from the surface of the material.

View detailsUVLED spot light source adopts controller + irradiation head + lens + heat dissipation mode, among which, UVLED spot light source controller is the standard product, irradiation head size is available in four specifications, lens spot size is avai...

View details