Brief description of UV Conveyor for EV cable crosslink

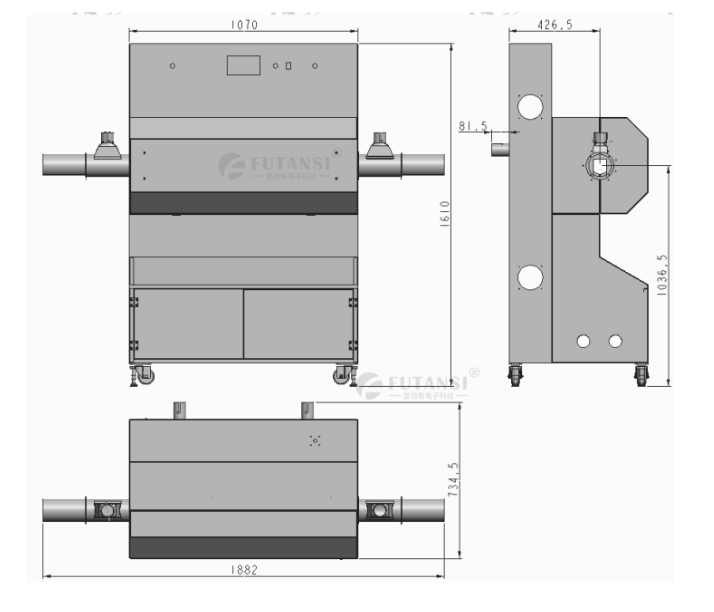

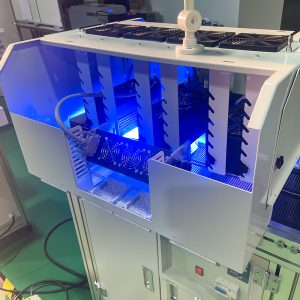

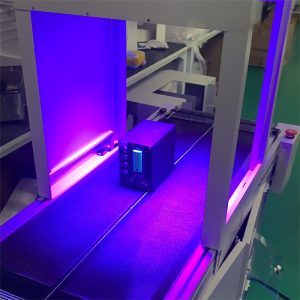

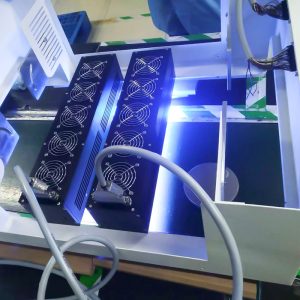

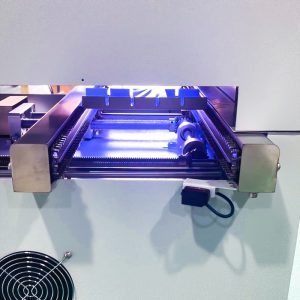

The UV LED conveyor adopts a high-efficiency UV LED light source to stimulate the photoinitiator in the cable material through specific wavelength UV irradiation, which rapidly triggers the cross-linking reaction of the material to achieve curing. In EV (Electric Vehicle) cable curing, the UV conveyor ensures the mechanical strength and electrical properties of the cables with its fast and uniform curing effect to meet the high standard requirements of the EV industry.

Advantages of UV Conveyors for EV cable crosslinker

- Stable light source: High quality UV LED curing system is used to provide stable curing effect.

- High light intensity: High light intensity ensures fast curing and improves production efficiency.

- Simple operation: user-friendly operation interface, one-button start, easy to get started.

- Less Maintenance: Optimised equipment design reduces maintenance requirements and lowers operating costs.

- Long life: Durable design extends equipment life and reduces replacement frequency.

- Cost-effective: Provide competitive price under the premise of quality assurance.

- In-line operation: supports in-line operation with other equipment in the production line to achieve automated production.

- Less harmful to human body: Compared with traditional UV lamps, UV LED curing systems is safer for human body.

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-拷贝-300x300.jpg)

-拷贝-300x300.jpg)

-拷贝-300x300.jpg)