UV radiation meters typically include UV radiation in specific ranges, such as UVA (320-400 nm), UVB (280-320 nm), and UVC (100-280 nm).

UV meters come in various forms, including handheld devices, wearable sensors, and stationary monitors. They typically use sensors that are sensitive to UV radiation to measure its intensity accurately. Some UV meters may also include additional features such as data logging, alarms for high UV levels, and Bluetooth connectivity for data transfer to other devices.

A UVA radiation meter is a specific type of device designed to measure the intensity of UVA radiation, which falls within the wavelength range of 320 to 400 nanometers (nm) on the electromagnetic spectrum.

It can be used to determine intensity (measured in mW/cm2) or total energy as derived from intensity and exposure time (measured in mJ/cm2). The unit is simple to operate and can be controlled manually via four buttons on the faceplate.

Ensuring and Sustaining a Light-Curing Process – A UV radiometer offers a measurable gauge to validate the proper functioning of the light-curing process within predefined parameters. Just as thermometers oversee thermal processes, radiometers afford crucial monitoring control for light-curing processes.

Assessing Transmission Rates Across Substrates – Employing a radiometer facilitates the measurement of light transmission rates across different wavelengths through substrates that absorb varying frequencies of energy. It is imperative to gauge the light intensity reaching the cure site beneath any intervening substrate to ensure an efficient curing process.

Radiometer Calibration: We strongly advise calibrating the UVEN300 radiometer every 12 months to uphold the instrument’s proper functionality. Calibration services are readily available.

UVA radiation meters typically use sensors specifically calibrated to detect UVA wavelengths accurately. These sensors may be integrated into handheld devices, wearable monitors, or stationary instruments. Some UVA meters may also include features such as data logging capabilities, alarms for high UVA levels, and connectivity options for data transfer and analysis.

]]>This article explores the significant impact of UV curing light and provides insights into selecting the appropriate UV curing system for optimal.

UV curing is a process widely employed in producing passive optical devices such as waveguides, lenses, and optical fibers. It involves the use of UV light to initiate a photochemical reaction in photosensitive materials, transforming them from a liquid or gel state to a solid state. This curing process ensures the integrity and reliability of optical components, contributing to their performance and longevity.

Impact of UV Curing Light on Passive Devices:

Bonding and Encapsulation: UV curing light is instrumental in bonding and encapsulating components of passive devices, such as waveguide substrates and optical fibers. It facilitates the formation of strong and durable bonds, ensuring the structural integrity of the devices and maintaining optical performance.

Coating and Protection: UV curing light is used in the application of protective coatings on optical surfaces to enhance their durability and resistance to environmental factors. These coatings shield the passive devices from moisture, dust, and mechanical damage, prolonging their lifespan and reliability.

Precision and Control: The precise control of UV curing light enables manufacturers to achieve uniform and consistent curing results, ensuring the dimensional accuracy and optical properties of passive devices. This level of precision is essential for meeting stringent performance requirements in optoelectronics applications.

Selecting the Right UV Curing Light:

- Wavelength Compatibility: Choose a UV-curing light source with a wavelength that matches the absorption spectrum of the photosensitive materials used in passive device fabrication. This ensures efficient curing and prevents damage to the materials.

- Intensity and Irradiance: Opt for a UV curing system with sufficient intensity and uniform irradiance across the curing area to achieve consistent curing results. High-intensity UV light accelerates the curing process, reducing cycle times and enhancing productivity.

- Control and Monitoring Features: Look for UV curing lights equipped with advanced control and monitoring features, such as adjustable intensity, exposure time, and real-time monitoring of UV output. These features provide greater flexibility and precision in the curing process, enabling optimization of device performance.

- System Integration: Consider UV curing systems that can be seamlessly integrated into existing manufacturing processes, offering compatibility with automated assembly lines and ensuring smooth production workflows.

UV curing light plays a vital role in the fabrication and assembly of passive optical devices in the optoelectronics industry, contributing to their performance, reliability, and longevity. By selecting the right UV curing system and optimizing curing parameters, manufacturers can achieve superior results in passive device manufacturing, driving innovation and advancement in optical communications.

As the demand for high-performance optical components continues to grow, the importance of UV curing light in passive device fabrication cannot be overstated. By leveraging the capabilities of advanced UV curing technology, manufacturers can meet the evolving needs of the optoelectronics market and deliver cutting-edge solutions to customers worldwide.

Established in 2010, Futansi is a leading company specializing in the research, development, and manufacturing of UV light sources. Our primary focus lies in the production of UV LED light sources, flood light sources, area light sources, curing chambers, curing ovens, and customized automation solutions tailored to our clients’ specific needs.

]]>In today’s technological landscape, the integration of ultraviolet (UV) LED light source has surged across diverse sectors. Among these, the optics industry emerges as a prominent beneficiary, harnessing the power of UV Light-Curing equipment for a myriad of purposes. This discourse navigates through the nuances of UV curing technology and its profound implications within the optics domain.

Applications in the Optics Industry

1. Optical Fiber Coating:

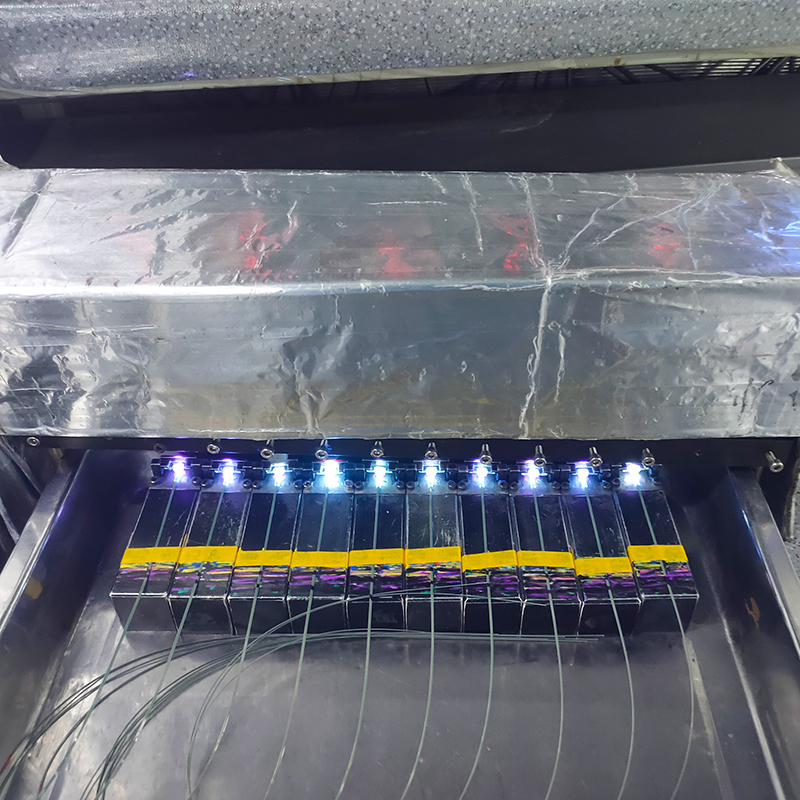

Optical fibers serve as the backbone of contemporary communication networks, enabling the seamless transmission of high-speed data across extensive distances. UV cure equipment play a pivotal role in the manufacturing process of optical fibers by curing the protective coatings applied to the fiber strands. The meticulous control offered by UV curing ensures uniform coating thickness and robust adhesion properties, thereby augmenting the performance and durability of optical fibers.

2. Lens Bonding:

UV curing adhesives emerge as an optimal solution for lens bonding owing to their rapid curing times and ability to forge strong, optically clear bonds. LED curing devices facilitate expedited assembly processes for manufacturers without compromising on bond strength or optical lucidity.

3. 3D Printing of Optical Components:

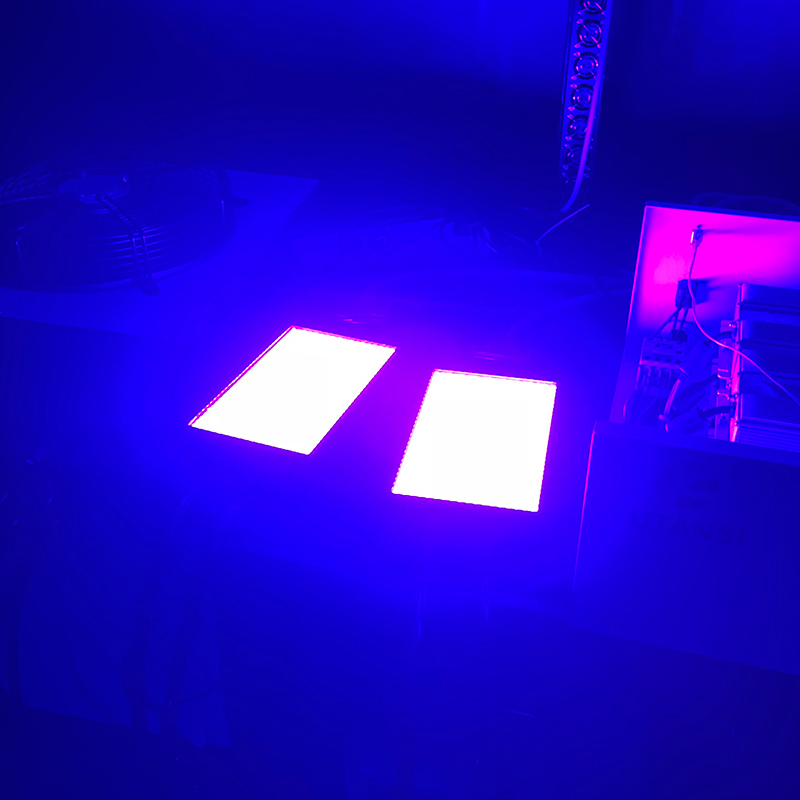

Additive manufacturing, particularly 3D printing, has revolutionized the fabrication of bespoke optical components with intricate geometries. UV-curable resins emerge as a preferred material choice for 3D printing due to their rapid curing capabilities and high-resolution output. Industrial UV curing equipment provide the requisite energy to solidify successive layers of resin, enabling the precise fabrication of optical prototypes, lenses, and customized components endowed with exceptional optical quality.

Advantages of UV Curing in the Optics Industry

- Speed and Efficiency: UV curing facilitates rapid curing times, thereby expediting production processes and enhancing throughput in optical manufacturing.

- Precision: UV curing enables meticulous control over curing parameters, ensuring uniformity and consistency in the fabrication of optical components.

- Optical Clarity: UV-curable materials culminate in optically clear bonds and coatings, preserving the pristine optical quality of finished products.

- Environmentally Friendly: UV curing obviates the necessity for solvent-based adhesives and coatings, thereby mitigating emissions of volatile organic compounds (VOCs) and minimizing environmental impact.

- Cost-effectiveness: The swift curing times and diminished energy consumption associated with UV curing translate into reduced overall production costs and heightened operational efficiency for optics manufacturers.

Future Trends and Innovations

As the optics industry undergoes continual evolution propelled by advancements in augmented reality (AR), virtual reality (VR), autonomous vehicles, and advanced imaging technologies, the demand for UV curing solutions is anticipated to soar. Future endeavors may revolve around the development of novel UV-curable materials tailored to specific optical applications, alongside the integration of UV curing systems into advanced manufacturing processes to bolster productivity and versatility.

Conclusion

UV curing systems occupy a central position in the optics industry, facilitating the expeditious and precise fabrication of optical components, coatings, and assemblies characterized by superior performance and reliability. From optical fiber coatings to lens bonding and 3D printing, the spectrum of UV curing technology applications continues to broaden, propelling innovation and efficiency across the optics manufacturing domain. As the industry embraces novel technologies and materials, UV curing stands poised to retain its prominence in optical manufacturing, empowering manufacturers to address the evolving demands of an increasingly interconnected world.

Founded in 2010, Futansi is a company specialising in the research, development and production of UV-emitting light sources. Futansi focus on the production and sales of UV LED light source, flood light source, area light source, curing chamber, curing oven and non-standard automation custom products.

Futansi’s sales service has covered many countries and regions in Asia, Europe, America, etc. Our products are widely used in many fields such as 3C electronics, furniture coating, spray painting and coding, fibre optic communication, medical manufacturing, industrial printers, rotary presses, offset presses, flexo presses, silk screen presses, exposure machines and so on.

First,the basic principle of UVLED light curing technology.

UVLED light curing is a technology that uses UVLED to emit ultraviolet light to cure the adhesive. When the UV radiation to the adhesive surface, the monomer and low molecular weight substances in the adhesive will cross-link reaction, the formation of high molecular weight polymer, so that the adhesive becomes strong, durable. UVLED light curing technology has the following characteristics:

1, high efficiency: UVLED light efficiency is high, can complete the light curing process in a short period of time to improve production efficiency.

2, low energy consumption: UVLED light source can efficiently convert electrical energy into light energy, compared to traditional UV lamps lower energy consumption.

3, safe and environmentally friendly: UVLED light source without ultraviolet radiation and mercury pollution, harmless to the environment and the operator.

Second, UVLED light curing in the production of photovoltaic silicon wafer applications

UVLED light curing in the production of photovoltaic silicon wafers are mainly used in the following areas:

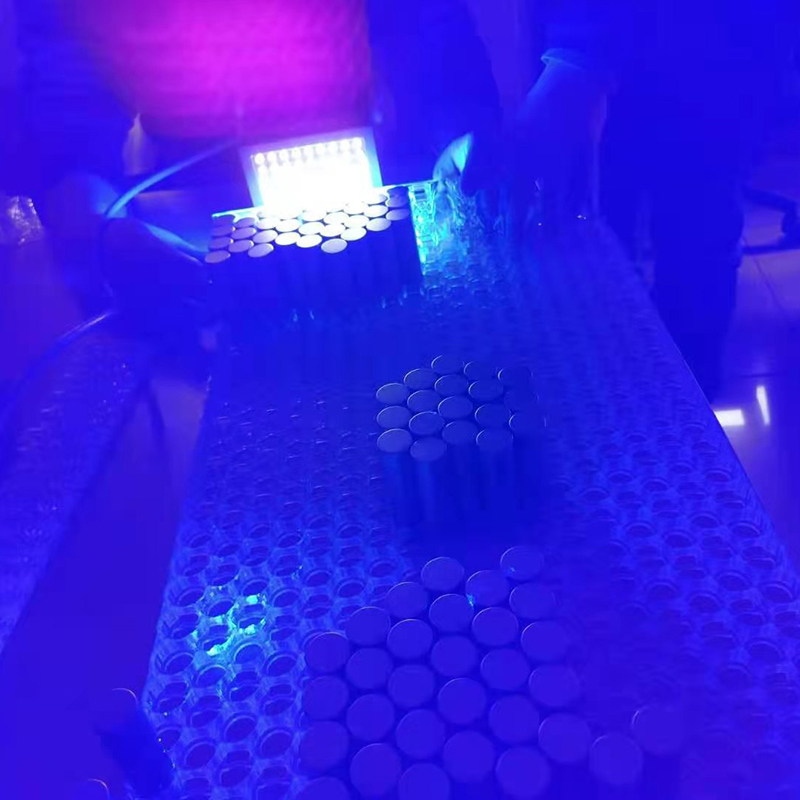

1, backplane curing

The backsheet is an important part of the photovoltaic cell, its main role is to protect the cell components and provide support. In the production process, the backsheet needs to be bonded to the cell and cured to make it tightly bonded. Traditional curing methods require the use of lamps, while UVLED light curing technology can achieve efficient, safe and stable curing effect.

2, silicon wafer bonding

UVLED light curing technology can achieve a more uniform and efficient curing effect, thus improving the quality and efficiency of the cell module.

3、Transfer film

In the manufacturing process of PV wafers, it is also necessary to use transfer film to make cell chips. Traditional curing methods require the use of ultraviolet lamps, while UVLED light curing technology can achieve a more efficient and safe curing effect, thereby improving the manufacturing efficiency and quality of battery components.

Third, the advantages of UVLED light curing technology

The use of UVLED light curing technology in the production process of photovoltaic silicon wafers has the following advantages:

1, energy saving and emission reduction

UVLED light source energy consumption is more than 50% lower than traditional UV lamps, while UVLED light source does not contain mercury and other harmful substances, can greatly reduce environmental pollution and harm.

2, improve production efficiency

UVLED light curing technology has a highly efficient, fast and uniform curing effect, can improve production efficiency and production quality.

3, reduce production costs

UVLED light source has a long life, low maintenance costs and other advantages, can reduce production costs.

Fourth, concluding remarks

The emergence of UVLED light curing technology has greatly contributed to the progress of photovoltaic wafer production technology, improving production efficiency and product quality, while also meeting environmental requirements. In the future, with the continuous development of UVLED technology, its application in the production of photovoltaic wafers will be more widespread.

]]>

2. wafer bonding: UVLED curing equipment can also be used for wafer bonding. UV curing adhesive can be used to bond wafers together, and UVLED can be used to cure the adhesive. Compared with traditional UV lamps, UVLED has the advantages of shorter curing time, higher productivity and better bonding strength.

3. Surface modification: UVLED curing equipment can be used to modify the surface of the wafer wafer. For example, UV-curable coatings can be applied to the wafer surface to improve its performance, such as adhesion, wear resistance and scratch resistance, etc. UVLED can be used to cure the coating to improve its performance.

4. slitting tape curing: UVLED curing equipment can also be used for slitting tape curing. Slitting tape is used to hold wafers in the wafer slitting process, UVLED can be used to cure the glue on the tape. Compared with traditional UV lamps, UVLED has the advantages of shorter curing time and better adhesion.

UVLED curing equipment has a wide range of applications in wafer production, including photoresist curing, wafer bonding, surface modification, and slitting tape curing. They are valuable tools in the semiconductor industry with advantages such as higher efficiency, lower energy consumption and better process control.

]]>

2. Automotive lamp manufacturing: UVLED light sources can be used in the manufacturing of automotive lamps. For example, UVLEDs can be used to cure the adhesive for lamp fixtures, improving product quality and durability. In addition, UVLEDs can also be used to manufacture interior lighting fixtures, dashboards, and entertainment systems, among others.

3. Air conditioning and filters manufacturing: UVLED light sources can be used in the manufacturing of automotive air conditioning and air filters. UVLEDs can emit UV radiation to kill bacteria and viruses in the air, thereby improving the quality of the air inside the vehicle.

4. Battery manufacturing: UVLED light sources can be used in the manufacturing of batteries. For example, UVLEDs can be used to cure the battery casing and bond battery components. In addition, UVLEDs can also be used to improve battery performance and lifespan.

Overall, UVLED light sources have a wide range of applications in the new energy automobile industry, including curing, lamp manufacturing, air conditioning and filter manufacturing, and battery manufacturing. These applications can improve production efficiency, reduce energy consumption, improve product quality and performance, and help protect the environment and improve the quality of the vehicle’s interior environment.

2. Optical sensing: UVLEDs can be used in optical sensing applications, such as sensing temperature, pressure, and strain. They can be used to measure changes in the refractive index of an optical fiber, which can be used to detect changes in the environment.

韵色.jpg)

3. Optical spectroscopy: UVLEDs can be used in optical spectroscopy applications, such as fluorescence spectroscopy and Raman spectroscopy. They can be used to excite fluorescent molecules or to generate Raman scattering for chemical analysis.

4. Manufacturing of optical components: UVLEDs can be used in the manufacturing of optical components, such as optical fibers, waveguides, and lenses. They can be used to cure adhesives and coatings, as well as to pattern and expose photoresist materials.

UVLED light sources have a wide range of applications in the optical communication industry, including fiber optic communication, optical sensing, optical spectroscopy, and manufacturing of optical components. They offer advantages such as high efficiency, low energy consumption, and precise control over the emission wavelength, making them a valuable tool for a variety of optical applications.

]]>Curing of adhesives and coatings: UV-LED light sources are widely used in the curing of adhesives and coatings on electronic components. UV-LEDs emit a narrow band of UV light, which can be precisely tuned to match the absorption characteristics of the material being cured. This results in faster curing times, higher production rates, and better product quality compared to traditional UV lamps.

PCB manufacturing: UV-LED light sources are also used in the manufacturing of printed circuit boards (PCBs). UV-LEDs are used to expose and develop the photoresist layer on the PCB, which defines the circuit pattern. UV-LEDs offer several advantages over traditional UV lamps in this application, including higher resolution, better uniformity, and lower energy consumption.

Sterilization: UV-LED light sources can be used for sterilization of electronic components and devices. UV-C light, which has a wavelength of 200-280 nm, is effective at killing bacteria, viruses, and other microorganisms. UV-LEDs can be used to deliver UV-C light in a controlled and targeted manner, making them ideal for sterilization applications.

Inspection: UV-LED light sources can be used for inspection of electronic components and devices. UV light can reveal defects and contaminants that are not visible under visible light. UV-LEDs can be used to provide a consistent and uniform source of UV light for inspection, resulting in better product quality.

Overall, the main advantages of UV-LED light sources in the production of electronic components include higher efficiency, lower energy consumption, better product quality, and increased process control and flexibility.

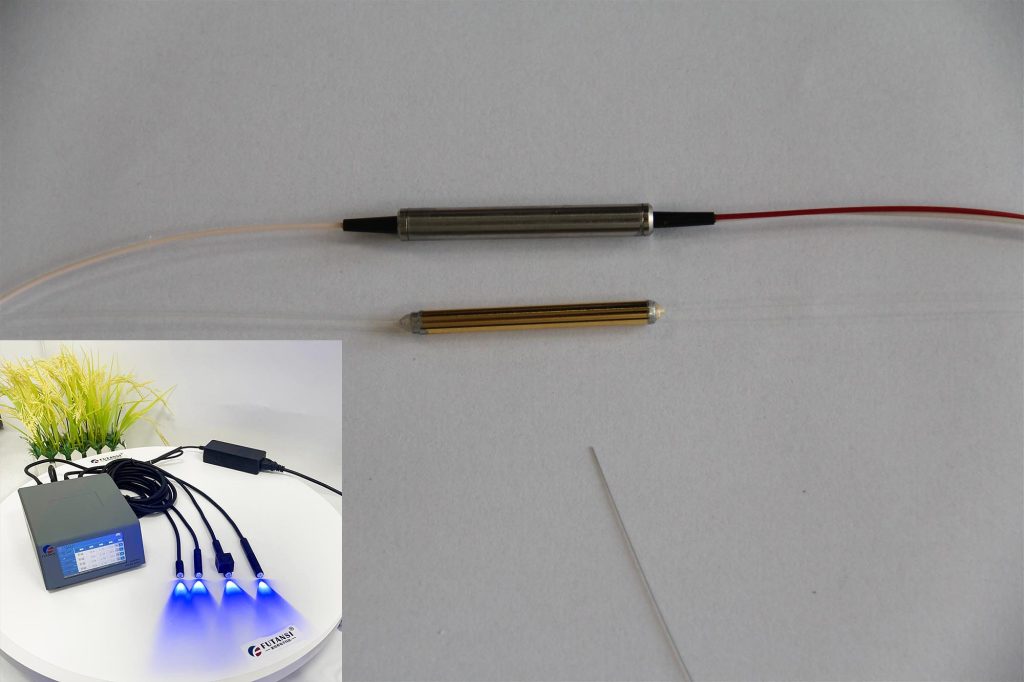

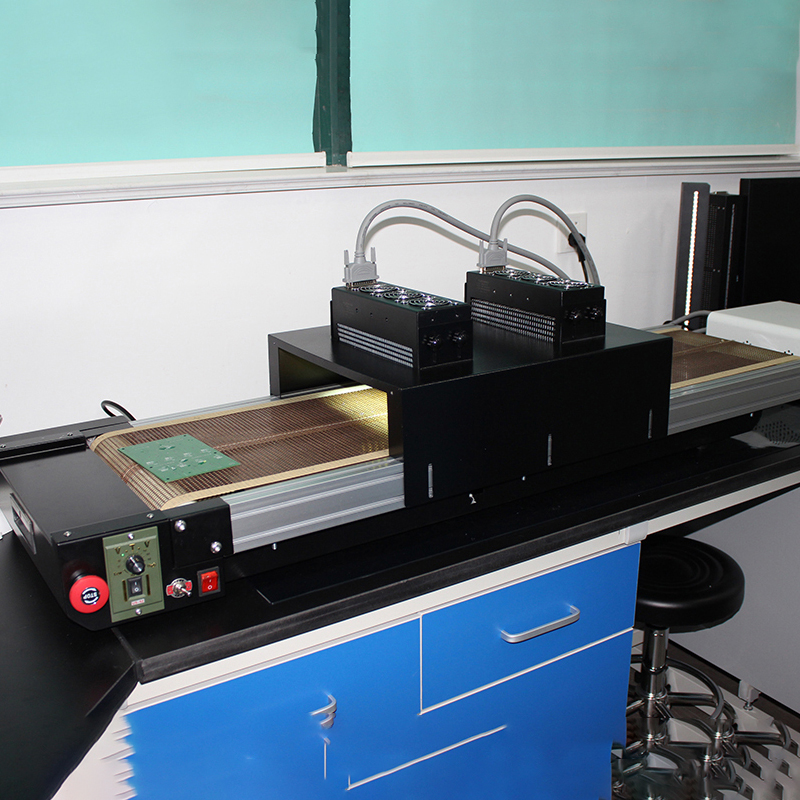

]]>FUTANSI (Shanghai) Electronic Technology Co., Ltd. produces UV LED curing equipment, including UVSP, UVLN, and UVSF models. These devices utilize UV curing technology to solidify ink, paint, adhesives, and other UV-sensitive materials through a polymerization process. As an energy-efficient, environmentally friendly, and safe light source, UV LED is a high-tech product that is poised to replace traditional electrode type UV mercury lamps.

UV LEDs contain no mercury and produce no ozone. They overcome many limitations of traditional UV mercury lamps, such as needing a preheating period before reaching peak intensity. With ultra-low energy consumption and longer life, UV LEDs are being recognized as the optimal replacement for traditional UV mercury lamps.

FUTANSI UVLED curing equipment finds widespread use in fields like microelectronics, optical communications, medical devices, PCBs, optics, printing, and academic research institutions.

1.2 Related Instructions

This instruction manual is a vital document that guides users in the correct operation of the equipment. To ensure safety, users must follow the specifications outlined in the manual and operate the equipment accordingly. Compliance with local security regulations and safety rules is also essential.

Please read this manual carefully before using the device. It should remain readily accessible to users and stored securely. If you have any questions, please contact the manufacturer (see section “9-customer service” for detailed information).

1.3 Liability Statement

The instruction manual has been written meticulously by our engineers, drawing upon relevant regulations, standards, and our accumulated knowledge and experience in the UV field.

However, FUTANSI (Shanghai) Electronic Technology Co., Ltd. will not bear any legal or civil liability for direct or indirect losses resulting from:

- Non-compliance with the manual’s instructions

- Improper use of the equipment

- Untrained personnel operating the equipment

- Ignoring error messages or malfunctions

- Continuing to use defective devices

- Unauthorized modifications/alterations

- Inadequate wiring according to electrical standards

- Electric shocks from touching with wet hands

- Not wearing protective gear during operation

- Burns from touching the device surface immediately after use

- Personal injury or damage caused by using the equipment near water sources or in damp places

- Electric shock or other accidents during thunderstorms

- Using the device in environments with security risks.

3. Technical Parameters

The spot light source is a critical component of the UVLED curing systems. Its function and design specifications play a significant role in the performance of the equipment. Specific technical parameters will vary based on the model and manufacturer’s design, so for detailed information, please refer to the specific product manual or consult with the manufacturer directly.

Please note that this section should be expanded upon with more specific information about the spotlight source, such as its wavelength range, power output, cooling requirements, and so on. This information is typically provided by the manufacturer or can be found in the product manual.

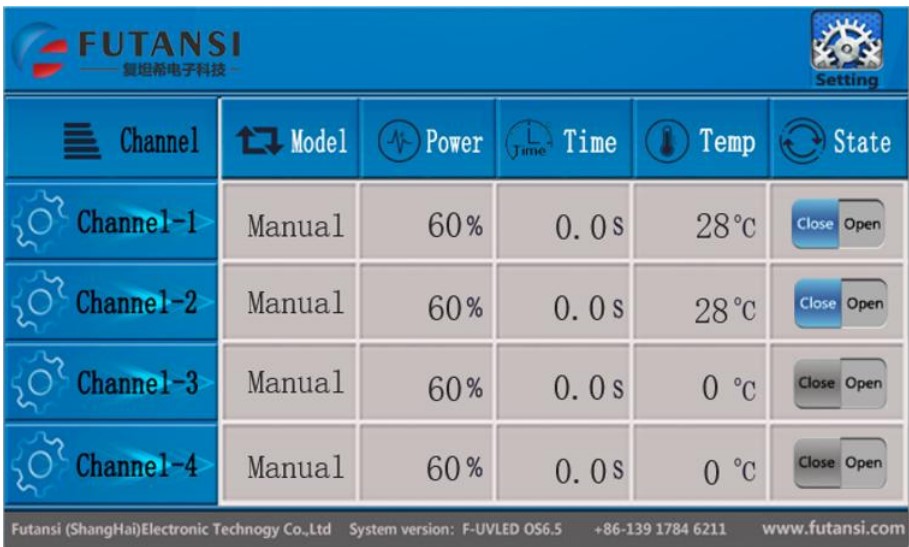

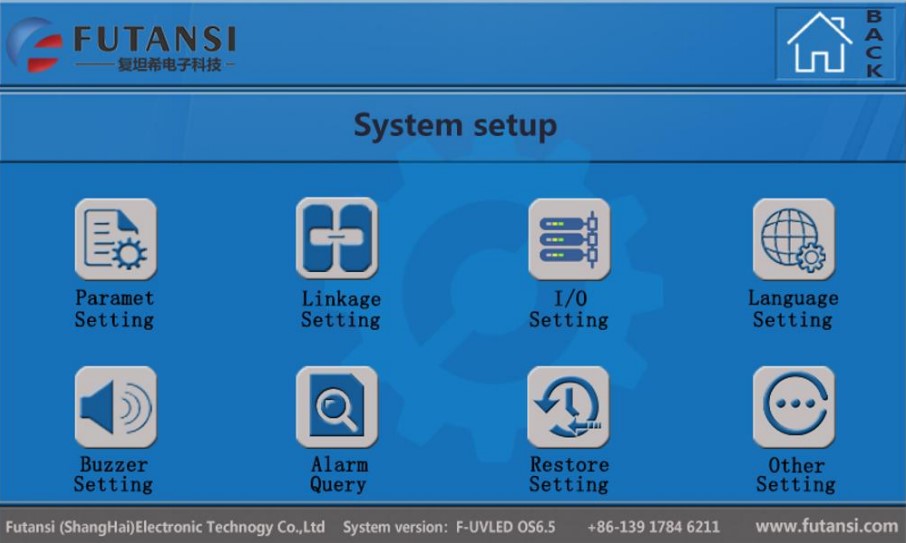

4. System Setup Operation Instructions (System Setup Password: 2018)

Work Main Interface

The “No-detection Main Interface” is the primary operational screen of the UVLED curing machine when no active detection tasks are underway. It displays key system parameters and provides menu options for setting up and starting new tasks.

Due to the specific interface design and functions varying from model to model, it’s essential to refer to the manufacturer-provided product manual or consult directly with the manufacturer for detailed operational instructions.

Please note that this section should be expanded upon with more specific information about navigating the “No-detection Main Interface”, such as how to access various menu options, initiate a detection task, or adjust system settings. This information is typically provided by the manufacturer or can be found in the product manual. Notes:

Notes:![]() The temperature can be detected normally, which indicating that the LED light source is connected properly and can be used normally.

The temperature can be detected normally, which indicating that the LED light source is connected properly and can be used normally. ![]() It indicates that the LED light source is running.

It indicates that the LED light source is running. ![]() It means that no LED light source is detected. In this state, the OFF/ON is invalid, and the click is not reflected.

It means that no LED light source is detected. In this state, the OFF/ON is invalid, and the click is not reflected.  It indicates the temperature abnormality alarm, click to cancel the alarm. When this warning icon appears during operation, it indicates that the UV light source temperature is too high. Please check if the heat sink is working properly.

It indicates the temperature abnormality alarm, click to cancel the alarm. When this warning icon appears during operation, it indicates that the UV light source temperature is too high. Please check if the heat sink is working properly.  It indicates that the LED is abnormal. Click to cancel the alarm. When this alert icon appears during operation, it indicates that the LED is shorted or open. Please check if the LED light source is lit normally. If you cannot solve the problem, please contact the company in time. *If some kinds of device encountered the problem on this page, it means that the water cooler is not connected or there is something wrong with the water cooler . Please check the external water cooling equipment. If the water cooling should connected to the water cooling machine, the water cooling machine must be turned on first, otherwise an alarm will be given.

It indicates that the LED is abnormal. Click to cancel the alarm. When this alert icon appears during operation, it indicates that the LED is shorted or open. Please check if the LED light source is lit normally. If you cannot solve the problem, please contact the company in time. *If some kinds of device encountered the problem on this page, it means that the water cooler is not connected or there is something wrong with the water cooler . Please check the external water cooling equipment. If the water cooling should connected to the water cooling machine, the water cooling machine must be turned on first, otherwise an alarm will be given.

4.2 System settings System settings main interface

4.3 Pedal Setting

The foot start mode is divided into pulse and low level mode. The default open state is: pulse

Pulse: Press the foot switch to start the irradiation, and stop the irradiation when you

press it again.

Low level: Depress the foot switch to start irradiation, and stop irradiation when released.

Overlay mode: not used by default, only used in special pipelines.

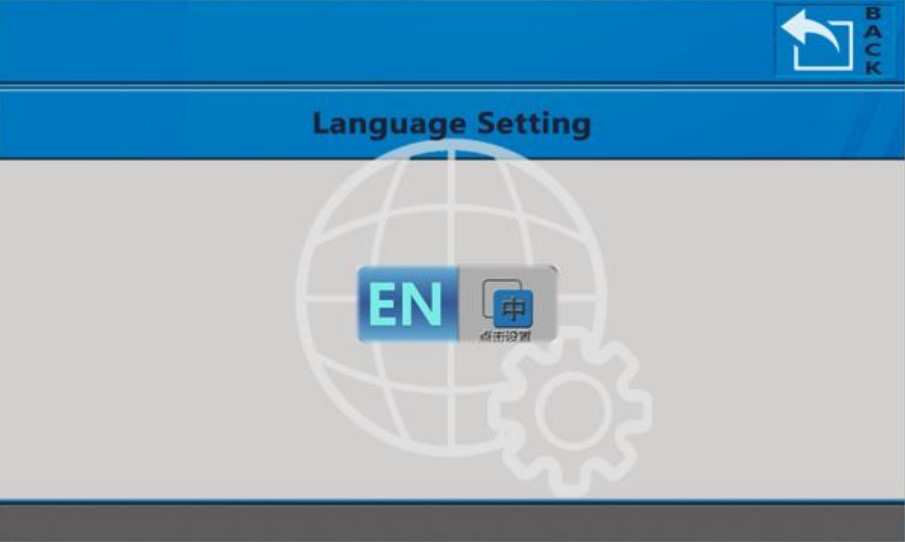

4.4 Language Setting

It supports switching of Chinese and English. Default language is Chinese, click to switch.

LEDUV curing light sources in UV ink curing within three broad applications:

1. Large-Format Inkjet Printing

The use of UV ink in large format inkjet printing is widespread, a fact reflected by the expanding installation base of UV inkjet printers. UV inkjet printing enhances image durability and printer head performance, enabling printing on a diverse range of substrates. Given the impressive results of LEDUV curing light sources in UV ink curing, a growing number of inkjet printers are adopting them for ink curing.

2. Industrial or Decorative Printing

Direct printing using UV inkjet technology on various materials like glass, metal, and ceramics sidesteps the need for pre-treatment of substrate surfaces. This advantage propels its continual adoption in industrial applications and decorative printing fields. When choosing LEDUV inkjet printing, it’s crucial to select a corresponding LEDUV curing light source. Fotanxi Electronic Technology provides LEDUV curing light sources that demonstrate excellent compatibility with multiple brands of UV ink, delivering superior curing results.

3. Label Printing and Packaging Printing

UV inkjet printing has also carved a niche for itself in label and packaging printing. A growing number of industry professionals value the benefits of UV inkjet printing, employing LEDUV curing light sources for their curing needs. The speed and quality offered by this method are evident advantages over manual operation, making the process more intelligent and efficient.

]]>