LED UV curing systems

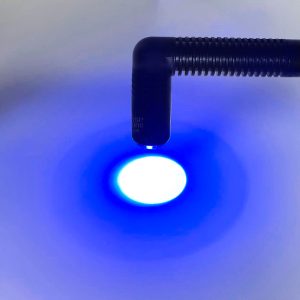

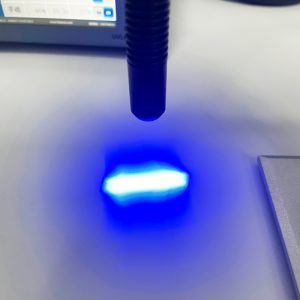

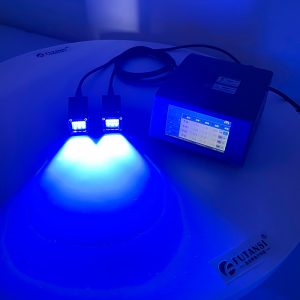

LED UV spot curing systems- Wave365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

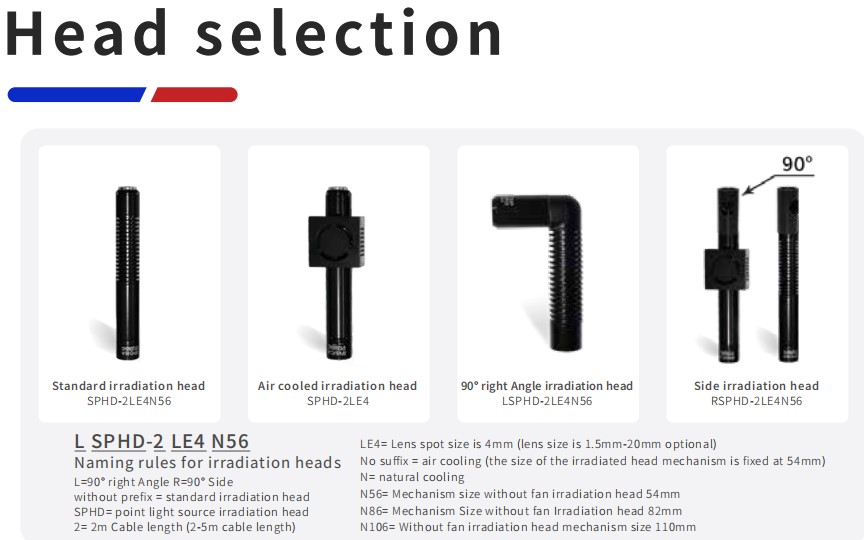

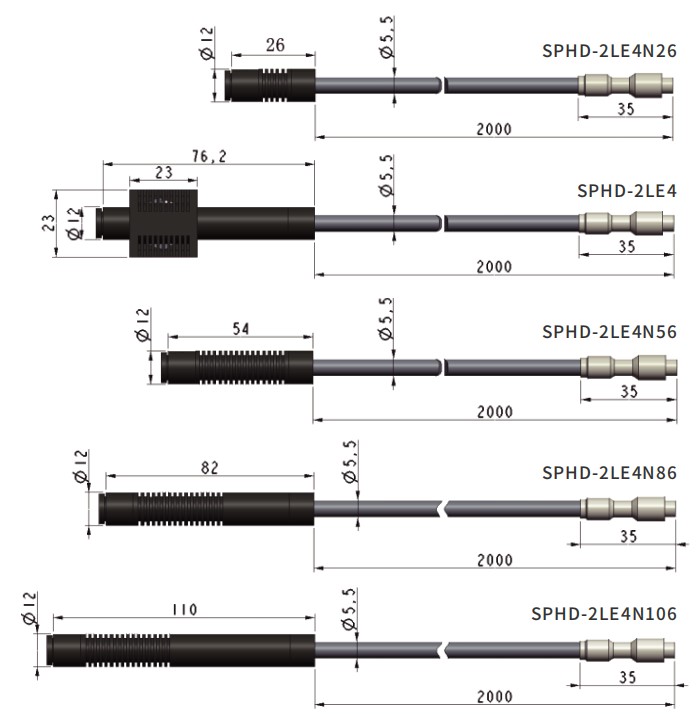

- Spot size∅1.5/2/3/4/5/6/7/8/10/12/15/18/20mm

- CoolingFans / Nature

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of the product

LED UV curing systems are advanced devices used in various industries for curing adhesives, coatings, and inks.

LED UV Technology: LED UV curing systems utilize light-emitting diodes (LEDs) to generate UV light in specific wavelengths. These LEDs emit light in the ultraviolet spectrum, typically in the UVA range (around 365-405 nanometers).

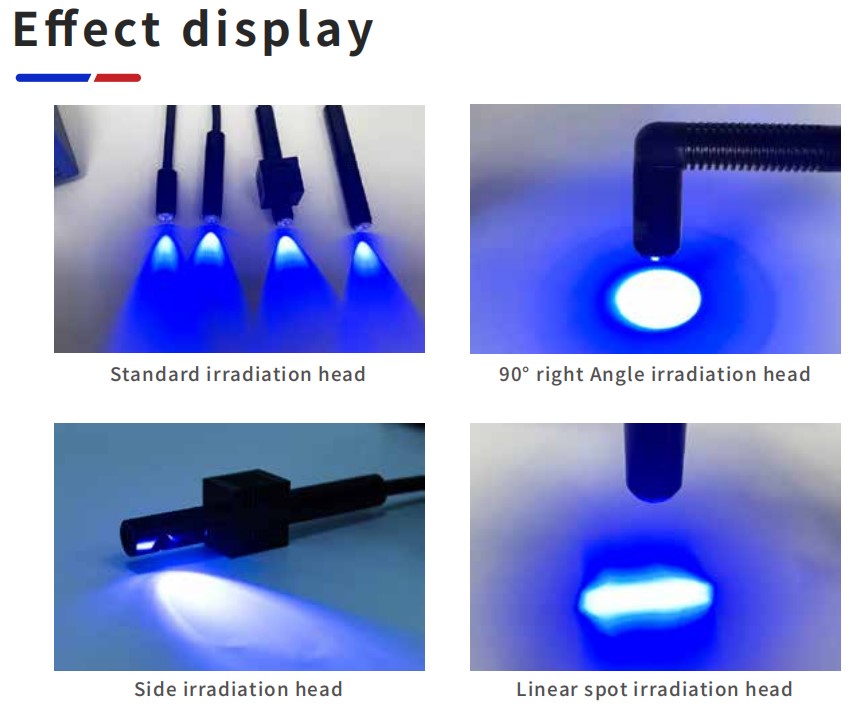

Spot Curing: spot curing systems focus UV light precisely on the area requiring curing. This targeted approach allows for faster and more efficient curing while minimizing heat generation and potential damage to surrounding materials.

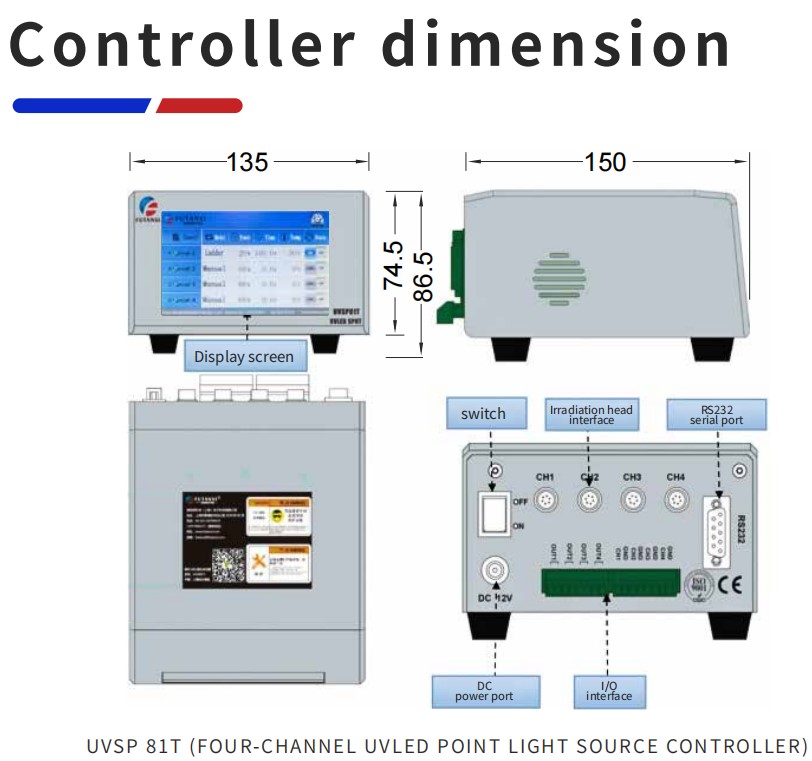

UV spot curing systems using touch screen control, power adjustable (10%-100%), can be set freely irradiation time. The equipment is small, easy to install and can be used with assembly line workshop.

Product Applications

LED UV curing systems find applications in various industries such as electronics, medical devices, automotive, aerospace, and optics. They are used for bonding, sealing, encapsulating, coating, and marking of components.specific applications can refer to the following:

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

photovoltaic chips, lithium battery module curing;

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

10、ink printing

screen printing label printing.

Product Advantages

Energy Efficiency: LED UV curing systems consume less energy compared to traditional UV lamps, resulting in lower operating costs.

Instant On/Off: LED UV lights can be switched on and off instantly, eliminating warm-up times and improving process efficiency.

Longevity: LED UV curing systems have a longer lifespan than traditional UV lamps, reducing maintenance costs and downtime.

Environmental Friendly: LED UV curing systems typically produce less heat and do not contain mercury, making them environmentally friendly.

Control and Monitoring: Futansi’ LED UV curing systems come with features for precise control and monitoring of curing parameters such as intensity, exposure time. This ensures consistent and reliable curing results.

Customization: These UV curing systems can be customized to meet specific application requirements, including different wavelengths for curing different types of materials and formulations.

Safety Considerations: While LED UV systems are generally safer than traditional UV lamps, proper safety precautions should still be observed, such as wearing appropriate personal protective equipment (PPE) and ensuring adequate ventilation in the workspace.

Overall, LED UV curing systems offer a modern, efficient, and versatile solution for various curing applications across industries, contributing to improved product quality and manufacturing efficiency.

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

韵色-300x300.jpg)