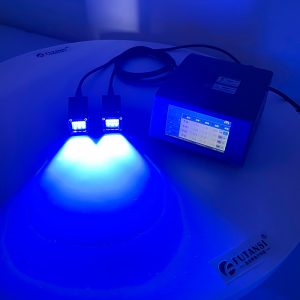

LED spot curing system

UV LED spot curing system- Wavelength365/385/395/405nm(Customised)

- ApplicationsUV adhesive/resin/ink curing

- Lens Diameter∅1.5/2/3/4/5/6/7/8/10/12/15/18/20mm

- Cooling methodFans / Nature

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of LED UV curing system

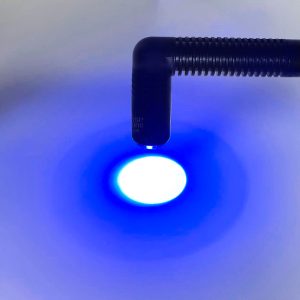

LED UV spot curing system is a technology used for curing or drying materials, typically in industrial applications.

The system uses LED (Light Emitting Diode) lamps that emit ultraviolet (UV) light, these LED lamps emit light in the UV spectrum, typically in the UVA or UVB range. When materials such as coatings, inks, adhesives, or resins are exposed to UV light, they undergo a photochemical reaction called curing or polymerization. This reaction causes them to solidify or harden.

In a UV LED curing system, multiple spot curing system are arranged in a line. Objects or materials to be cured pass under this line of lamps on a conveyor belt or similar mechanism.

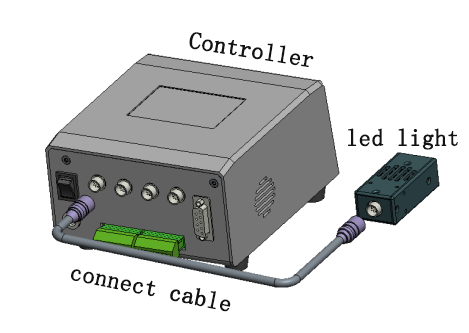

The spot curing system include controls to adjust the intensity of the UV light and the working time to achieve the desired curing effect.

Product Applications

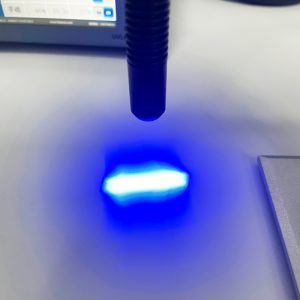

Futansi UV curing spot light is mainly used for UV adhesive, UV ink, UV varnish, UV paint, UV coating and other light-sensitive materials curing role, so that its surface glossy and bright, with good weather resistance, waterproof, friction resistance, acid and alkali resistance and other high-strength protection role. 365nm UV Spot Curing Systems application areas are wide, mostly used in ink printing, industrial products fixed, specific applications can refer to the following:

1、Printing Industry: UV LED Curing are commonly used in the printing industry for curing UV-curable inks on materials such as paper, plastic, and metal.

2、Electronics Manufacturing: LED UV curing is employed for curing adhesives and encapsulants in the assembly of electronic components.

3、Medical Device Manufacturing: In the production of medical devices, LED UV curing systems are used for bonding, sealing, and coating applications.

4、Automotive Industry: LED Curing Solutions is utilized for curing coatings and adhesives in automotive manufacturing processes, such as bonding windshields and assembling interior components.

5、Coatings and Finishing: They are used for curing UV coatings on surfaces like wood, glass, and metal for protection or aesthetic enhancement.

Product Advantages

1、High quality LED beads

Advantages such as high energy, strong light and long service life;

2、Single-wavelength LED ultraviolet light source

UV curing common output of 365nm, 385nm, 395nm, 405nm, no thermal radiation;

3、 LED UV curing light with low heat radiation

LED UV curing system using high power LED beads, emitting 365/385/395/405/470/525nm single-output UV light source, no infrared wavelength, the irradiated substrate surface temperature rise of no more than 5 ℃, no thermal radiation damage to the substrate surface, suitable for heat-sensitive material surface drying;

4、Multi-channel working mode

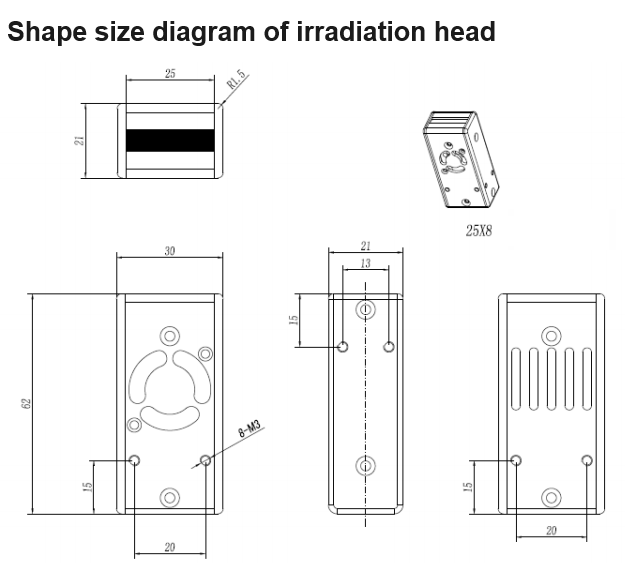

Standard with a four-head UV Spot Systems, according to the actual use of the situation, choose 1-4 irradiation heads alone or synchronous work, effective costly;

5、Low power consumption

Through the led chip for electrical energy; light energy conversion, less energy loss, low power consumption, about one tenth of the traditional UV mercury lamp, Spot UV irradiation systems can save a lot of electricity consumption each year;

6、Clean and environmental protection without pollution

UV LED curing machine does not contain mercury metal harmful substances, does not produce ozone when used, belongs to a clean and environmentally friendly energy;

7, small size, small footprint

LED Spot Curing covers an area far less than the traditional UV mercury lamp lamp, can be customized shape size and irradiation area, the average size of about 1/10 of the UV light type, light weight, small physical strength, suitable for use in different working environments;;

8、Long service life

LED UV curing through LED beads, its use time is more than 20,000h on average, compared to the traditional UV mercury lamp service life (average use time is about 800h) is much longer, can instantly light up/off led ultraviolet light source, not affected by switch closure;

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

Download documents

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

韵色-300x300.jpg)