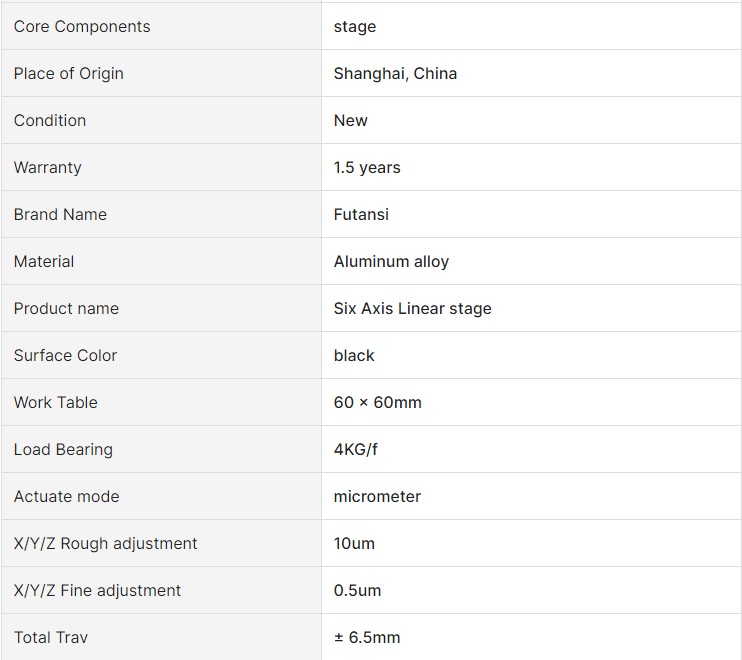

Precision Six Axis Manual Stages and Slides

Multi-axis Manual Positioning Guide- Platform Size60mm

- componentX,Y,Z, θX,θY, θZ

- Travel distance6.5mm @ 0.3mm

- Accuracy5um

- Load capacity4KG/F

- MaterialAlumimum alloy

- Surface ColorBlack

Precision Six-Axis Manual Stages

Precision six-axis manual stages, also known as six-degree-of-freedom (6-DOF) stages, are sophisticated mechanical platforms designed to provide precise positioning and orientation control in multiple axes. These stages play a pivotal role in various industries where intricate manipulation and accurate alignment are paramount. This article delves into the diverse applications of precision six-axis manual stages, showcasing their versatility across different fields.

Product Brief description

Aluminum Stages

Our Precision Six Axis Manual Stages and Slides are constructed from aluminum, a cost-effective, lightweight material resistant to cold flow or creep with a good stiffness-to-weight ratio. Aluminum stages can be used for a wide variety of experiments and are well suited for general laboratory applications. These manual aluminum stages are offered in a wide variety of sizes and travel ranges to suit your application.

Product Applications

1. Microelectronics and Semiconductor Manufacturing: In the microelectronics industry, where miniaturization is a key focus, precision is crucial. Six-axis manual stages find application in tasks such as aligning semiconductor wafers, positioning probes for testing, and manipulating delicate components during the manufacturing and assembly processes. Their ability to offer precise control in all six degrees of freedom is instrumental in ensuring the accuracy demanded by the semiconductor industry.

2. Optics and Photonics: Precision is the essence of optical systems, and six-axis manual stages play a vital role in aligning optical components such as lenses, mirrors, and laser systems. These stages enable engineers and researchers to fine-tune the alignment of optical elements in experimental setups, testing environments, and manufacturing processes. The versatility of six-axis stages is particularly advantageous in the development of complex optical systems.

3. Medical Device Manufacturing: In the production of medical devices, especially those involving intricate components or precision optics, six-axis manual stages are employed for tasks such as aligning lenses in imaging devices, positioning sensors, or adjusting the alignment of components in surgical instruments. The precise control offered by these stages ensures the reliability and accuracy of medical devices used in diagnostics and treatments.

4. Aerospace and Defense: The aerospace and defense industries leverage six-axis manual stages for tasks ranging from aligning components in satellite systems to testing and calibrating optical instruments on aircraft. The stages play a critical role in the manufacturing, assembly, and maintenance of aerospace systems where accuracy is paramount for optimal performance.

5. Research and Development: In research laboratories across various disciplines, precision six-axis manual stages are indispensable tools. Researchers use these stages to manipulate and position components in experiments related to physics, materials science, and engineering. Their versatility allows for a wide range of applications, including microscopy, spectroscopy, and other advanced research techniques.

6. Automated Inspection Systems: In industries such as quality control and automated inspection, six-axis manual stages are integrated into systems for inspecting and testing manufactured products. These stages enable precise positioning of inspection tools, cameras, or sensors, contributing to the accuracy and efficiency of inspection processes.

7. Robotics and Automation: In robotics research and the development of robotic systems, six-axis manual stages are used to simulate and test the movement and control of robotic arms. Researchers can precisely position and orient components to validate control algorithms, test sensors, and optimize the performance of robotic systems.

Challenges and Considerations: While precision six-axis manual stages offer remarkable capabilities, their successful application requires consideration of factors such as load capacity, repeatability, and environmental conditions. Careful integration into specific workflows and systems is essential to maximize their effectiveness.

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

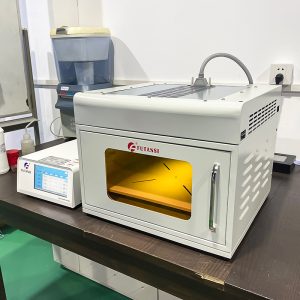

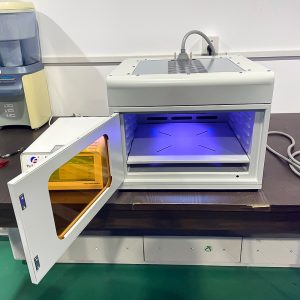

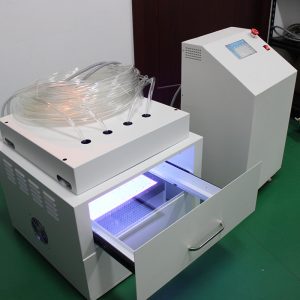

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)