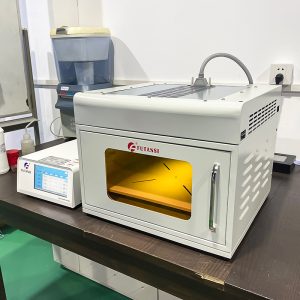

Brief description of the product

The heating element ensures that the material to be cured is at the optimal temperature for the curing process, ensuring maximum efficiency and quality. The temperature control system monitors and maintains the desired temperature, adjusting it as necessary to ensure consistent curing results.

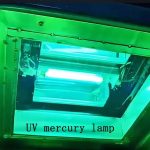

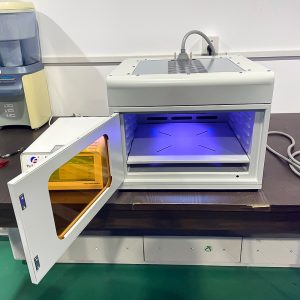

The UV light source is the heart of the curing oven, emitting UV radiation that initiates the chemical reaction that cures the material. The intensity and wavelength of the UV light must be carefully controlled to ensure complete curing without damaging the material.

Product Applications

Futansi UV curing oven can be used for UV adhesive, UV ink, UV varnish, UV paint, UV coating and other photosensitive materials curing role, so that its surface glossy and bright, with good weather resistance, water resistance, friction resistance, acid and alkali resistance and other high-intensity protection role. uv light source application areas are wide, suitable for ink printing, industrial products fixed, specific applications can be referred to the following:

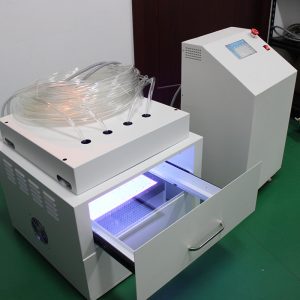

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

photovoltaic chips, lithium battery module curing;

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

10、ink printing

screen printing label printing.

Product Advantages

these components work seamlessly to provide a highly effective and efficient UV curing process. Proper maintenance and calibration of these components are essential to ensuring consistent and reliable curing results. Regular inspections and adjustments should be performed to ensure that the oven is operating at peak performance.

UV mercury curing ovens are essential tools in various industries, including printing, coating, and adhesives, due to their ability to quickly and efficiently cure UV-sensitive materials. These ovens use UV light emitted by mercury lamps to trigger a chemical reaction in the material, causing it to harden or cure.

To ensure consistent and effective curing, it is crucial to have precise temperature control in the UV mercury curing oven. Temperature plays a crucial role in the curing process, as it affects the rate and efficiency of the chemical reaction. If the temperature is too low, the curing process may be slow or incomplete, resulting in a weaker, less durable finished product. Conversely, if the temperature is too high, it can cause the material to cure too quickly, potentially leading to cracking or other defects.

Therefore, it is essential to invest in a UV mercury curing oven with advanced temperature control features. These features may include adjustable thermostats, sensors to monitor and regulate temperature, and even automatic shut-off mechanisms to prevent overheating. By carefully monitoring and controlling the temperature within the oven, users can ensure consistent, high-quality curing results.

In addition to temperature control, it is also important to consider other factors that can affect the curing process, such as the type and intensity of UV light, the thickness and composition of the material being cured, and the duration of exposure to UV light. By optimizing these variables and maintaining precise temperature control, users can maximize the efficiency and quality of their UV mercury curing oven.

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)