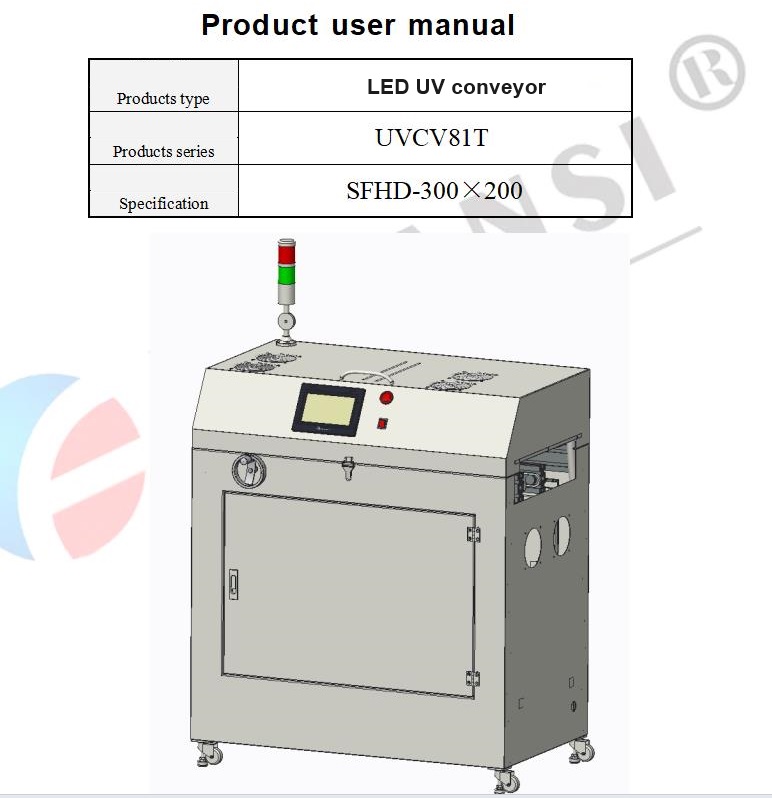

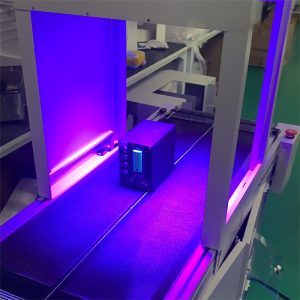

LED UV conveyor

PCBA curing- Wave365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

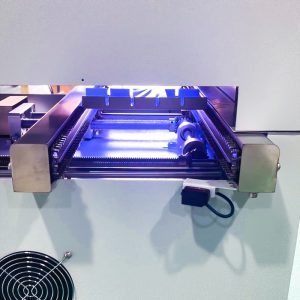

- Luminous size20mm-500mm long, 20-500mm wide

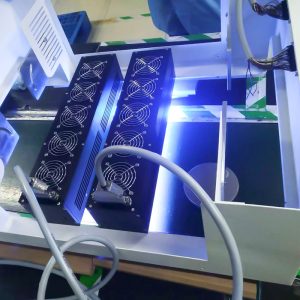

- CoolingFans / Water Cooling

- Light intensity10-10000mW/cm²

Related product literature downloads

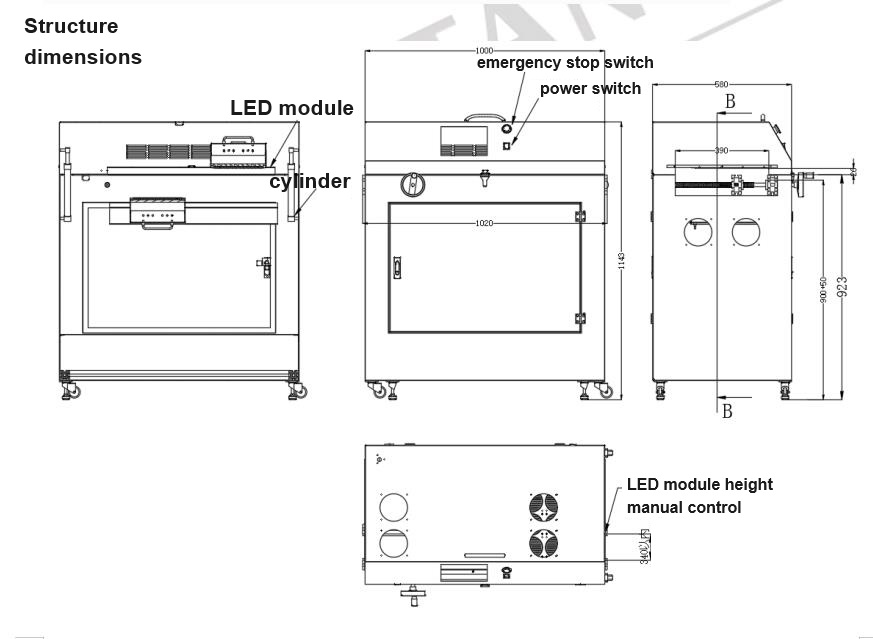

Brief description of UV Conveyor for PCB Platform with LED Light Source

In the realm of printed circuit board (PCBA) manufacturing, precision and efficiency are paramount.

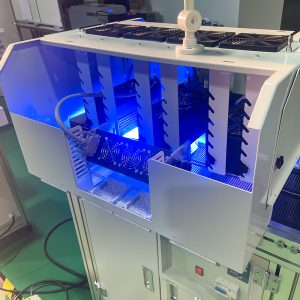

UV LED Curing conveyor, adopts advanced UV LED technology to achieve rapid curing through high-energy UV irradiation. The working principle is to use a specific wavelength of UV light to irradiate on the material, which triggers the chemical reaction of photosensitiser or photoinitiator to achieve the purpose of curing. This technology is widely used in electronic manufacturing, printing, coating, cosmetics and other industries, especially in the PCBA (Printed Circuit Board Assembly) industry, UV conveyor is indispensable equipment.

UV LED conveyor adopts touch screen control mode, power adjustable (10%-100%), free to set the irradiation time. The equipment is small in size, covers an area of less, easy to install, can be used with the assembly line workshop supporting.

Significance in PCB Manufacturing

- PCB manufacturing demands meticulous processes, and UV conveyors with LED light sources play a crucial role in enhancing the curing of coatings and adhesives. The uniform exposure to UV light ensures consistent curing across the entire PCB, contributing to the production of high-quality electronic components.

- The integration of LED light sources in UV conveyors is a game-changer. LEDs offer precise wavelength control, allowing targeted curing with minimal heat generation. The conveyor system ensures the PCB moves seamlessly through the curing process, maximizing efficiency and reducing the risk of uneven curing.

Advantages of UV Conveyors for PCBA Platforms

- Human-machine interface: intuitive operation interface simplifies the operation process and improves work efficiency.

- Superior materials: the selection of high-quality materials to ensure the durability and stability of the equipment.

- Stable quality: Strict quality control ensures the consistency of each curing oven’s performance.

- Simple operation: one button start, intelligent operation, reduce human error.

- Less Maintenance: Reasonable design, reduce maintenance needs, lower operating costs.

- Long life: durability design, prolong the service life of the equipment, reduce the frequency of replacement.

- Cost-effective: Provide competitive price under the premise of quality assurance.

- LED light sources emit minimal heat during the curing process. This is particularly advantageous in PCB manufacturing, where sensitive electronic components can be adversely affected by excessive heat. The reduced heat exposure ensures the integrity of the PCB components, contributing to the overall reliability of the electronic devices.

UV conveyor Applications

- Coating and Adhesive Curing The primary application of UV conveyors with LED light sources in PCB manufacturing is the curing of coatings and adhesives. Whether it’s solder mask coatings or adhesive bonding, the precise wavelength control of LEDs ensures thorough and efficient curing, leading to durable and reliable PCBs.

- In-Line Production Integration UV conveyors seamlessly integrate into the in-line production process, allowing for continuous and automated curing of PCBs. The conveyor system ensures a smooth and consistent workflow, reducing production time and increasing overall output.

UV conveyor Advantages

Technological innovation: UV LED curing technology continues to progress, bringing more efficient and environmentally friendly solutions to the industry.

Market Trend: With the improvement of environmental awareness, UV conveyor is gradually replacing the traditional mercury lamp curing equipment.

Customer Cases: We have many successful cases, customers all over the world, covering a variety of industries.

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-拷贝-300x300.jpg)

-拷贝-300x300.jpg)

-拷贝-300x300.jpg)