1.1 Brief Introduction

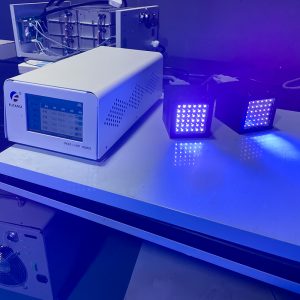

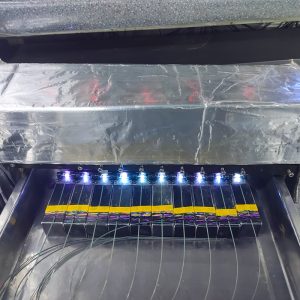

FUTANSI (Shanghai) Electronic Technology Co., Ltd. produces UV LED curing equipment, including UVSP, UVLN, and UVSF models. These devices utilize UV curing technology to solidify ink, paint, adhesives, and other UV-sensitive materials through a polymerization process. As an energy-efficient, environmentally friendly, and safe light source, UV LED is a high-tech product that is poised to replace traditional electrode type UV mercury lamps.

UV LEDs contain no mercury and produce no ozone. They overcome many limitations of traditional UV mercury lamps, such as needing a preheating period before reaching peak intensity. With ultra-low energy consumption and longer life, UV LEDs are being recognized as the optimal replacement for traditional UV mercury lamps.

FUTANSI UVLED curing equipment finds widespread use in fields like microelectronics, optical communications, medical devices, PCBs, optics, printing, and academic research institutions.

1.2 Related Instructions

This instruction manual is a vital document that guides users in the correct operation of the equipment. To ensure safety, users must follow the specifications outlined in the manual and operate the equipment accordingly. Compliance with local security regulations and safety rules is also essential.

Please read this manual carefully before using the device. It should remain readily accessible to users and stored securely. If you have any questions, please contact the manufacturer (see section “9-customer service” for detailed information).

1.3 Liability Statement

The instruction manual has been written meticulously by our engineers, drawing upon relevant regulations, standards, and our accumulated knowledge and experience in the UV field.

However, FUTANSI (Shanghai) Electronic Technology Co., Ltd. will not bear any legal or civil liability for direct or indirect losses resulting from:

- Non-compliance with the manual’s instructions

- Improper use of the equipment

- Untrained personnel operating the equipment

- Ignoring error messages or malfunctions

- Continuing to use defective devices

- Unauthorized modifications/alterations

- Inadequate wiring according to electrical standards

- Electric shocks from touching with wet hands

- Not wearing protective gear during operation

- Burns from touching the device surface immediately after use

- Personal injury or damage caused by using the equipment near water sources or in damp places

- Electric shock or other accidents during thunderstorms

- Using the device in environments with security risks.

3. Technical Parameters

The spot light source is a critical component of the UVLED curing systems. Its function and design specifications play a significant role in the performance of the equipment. Specific technical parameters will vary based on the model and manufacturer’s design, so for detailed information, please refer to the specific product manual or consult with the manufacturer directly.

Please note that this section should be expanded upon with more specific information about the spotlight source, such as its wavelength range, power output, cooling requirements, and so on. This information is typically provided by the manufacturer or can be found in the product manual.

4. System Setup Operation Instructions (System Setup Password: 2018)

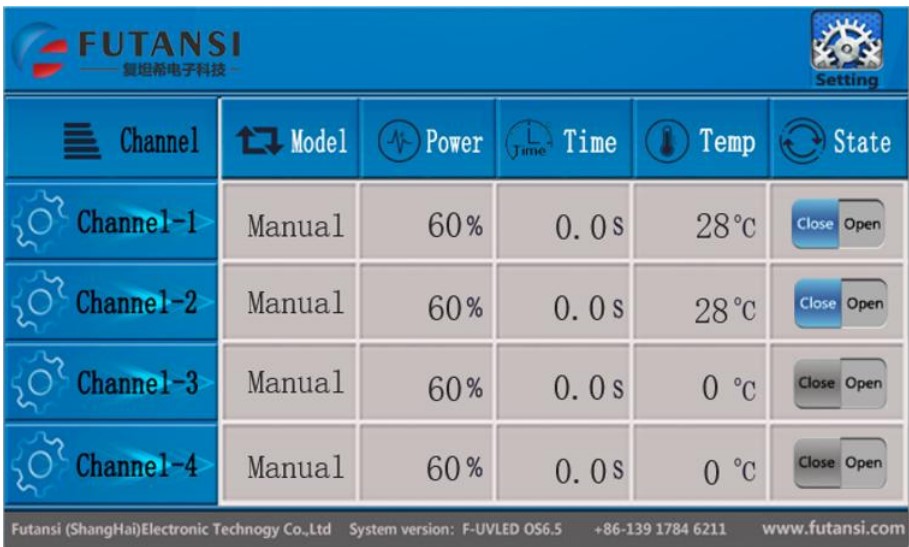

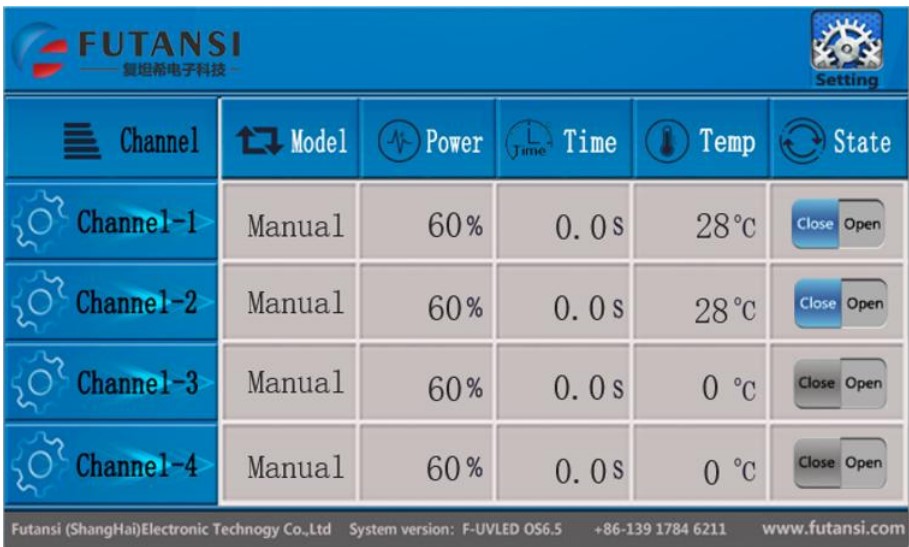

Work Main Interface

The “No-detection Main Interface” is the primary operational screen of the UVLED curing machine when no active detection tasks are underway. It displays key system parameters and provides menu options for setting up and starting new tasks.

Due to the specific interface design and functions varying from model to model, it’s essential to refer to the manufacturer-provided product manual or consult directly with the manufacturer for detailed operational instructions.

Please note that this section should be expanded upon with more specific information about navigating the “No-detection Main Interface”, such as how to access various menu options, initiate a detection task, or adjust system settings. This information is typically provided by the manufacturer or can be found in the product manual. Notes:

Notes: The temperature can be detected normally, which indicating that the LED light source is connected properly and can be used normally.

The temperature can be detected normally, which indicating that the LED light source is connected properly and can be used normally.  It indicates that the LED light source is running.

It indicates that the LED light source is running.  It means that no LED light source is detected. In this state, the OFF/ON is invalid, and the click is not reflected.

It means that no LED light source is detected. In this state, the OFF/ON is invalid, and the click is not reflected.  It indicates the temperature abnormality alarm, click to cancel the alarm. When this warning icon appears during operation, it indicates that the UV light source temperature is too high. Please check if the heat sink is working properly.

It indicates the temperature abnormality alarm, click to cancel the alarm. When this warning icon appears during operation, it indicates that the UV light source temperature is too high. Please check if the heat sink is working properly.  It indicates that the LED is abnormal. Click to cancel the alarm. When this alert icon appears during operation, it indicates that the LED is shorted or open. Please check if the LED light source is lit normally. If you cannot solve the problem, please contact the company in time. *If some kinds of device encountered the problem on this page, it means that the water cooler is not connected or there is something wrong with the water cooler . Please check the external water cooling equipment. If the water cooling should connected to the water cooling machine, the water cooling machine must be turned on first, otherwise an alarm will be given.

It indicates that the LED is abnormal. Click to cancel the alarm. When this alert icon appears during operation, it indicates that the LED is shorted or open. Please check if the LED light source is lit normally. If you cannot solve the problem, please contact the company in time. *If some kinds of device encountered the problem on this page, it means that the water cooler is not connected or there is something wrong with the water cooler . Please check the external water cooling equipment. If the water cooling should connected to the water cooling machine, the water cooling machine must be turned on first, otherwise an alarm will be given.

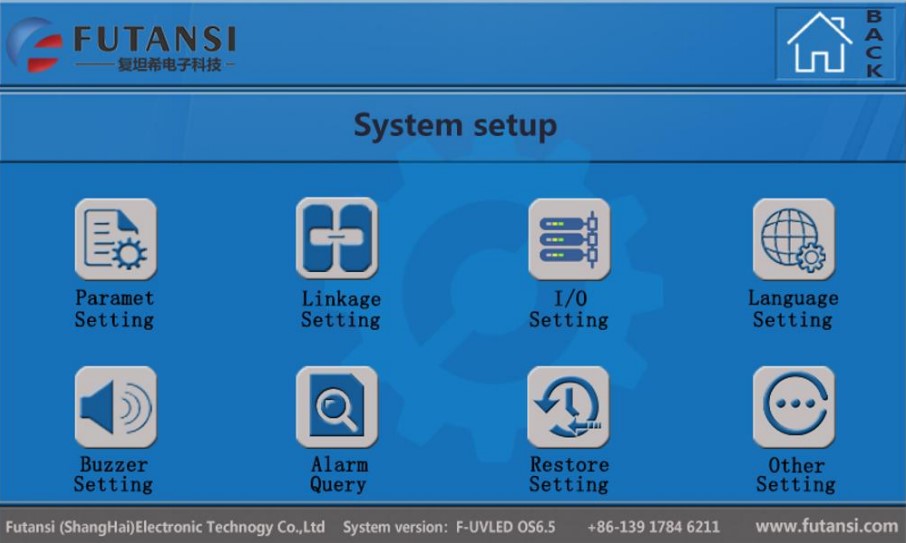

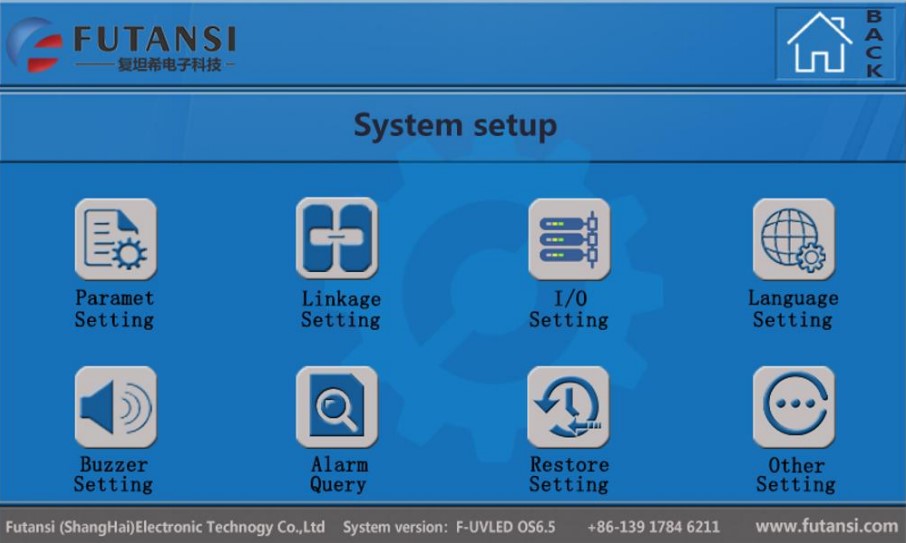

4.2 System settings System settings main interface

4.3 Pedal Setting

The foot start mode is divided into pulse and low level mode. The default open state is: pulse

Pulse: Press the foot switch to start the irradiation, and stop the irradiation when you

press it again.

Low level: Depress the foot switch to start irradiation, and stop irradiation when released.

Overlay mode: not used by default, only used in special pipelines.

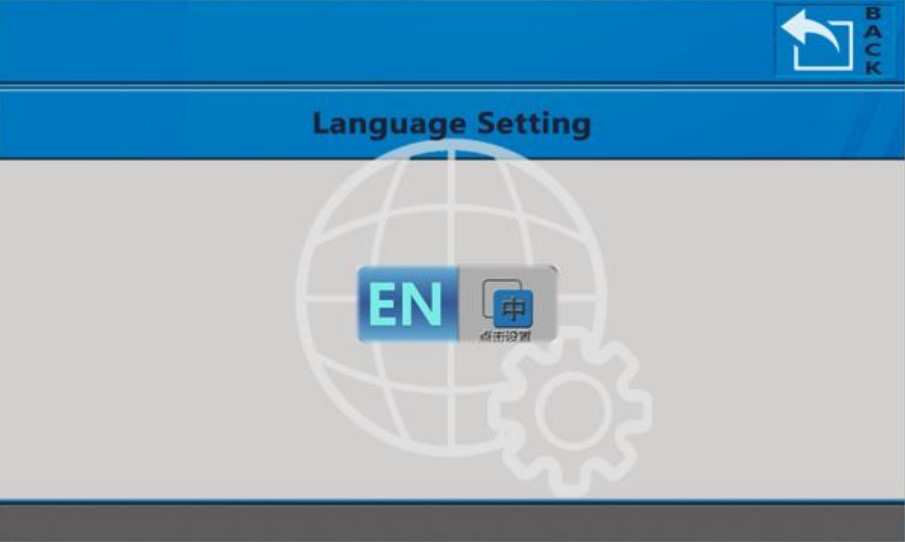

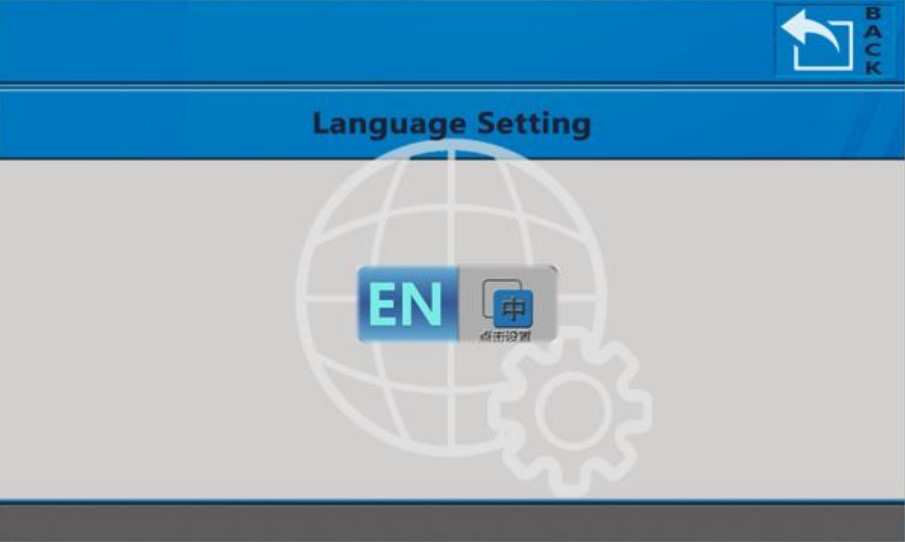

4.4 Language Setting

It supports switching of Chinese and English. Default language is Chinese, click to switch.

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

Notes:

Notes: It indicates the temperature abnormality alarm, click to cancel the alarm. When this warning icon appears during operation, it indicates that the UV light source temperature is too high. Please check if the heat sink is working properly.

It indicates the temperature abnormality alarm, click to cancel the alarm. When this warning icon appears during operation, it indicates that the UV light source temperature is too high. Please check if the heat sink is working properly.  It indicates that the LED is abnormal. Click to cancel the alarm. When this alert icon appears during operation, it indicates that the LED is shorted or open. Please check if the LED light source is lit normally. If you cannot solve the problem, please contact the company in time. *If some kinds of device encountered the problem on this page, it means that the water cooler is not connected or there is something wrong with the water cooler . Please check the external water cooling equipment. If the water cooling should connected to the water cooling machine, the water cooling machine must be turned on first, otherwise an alarm will be given.

It indicates that the LED is abnormal. Click to cancel the alarm. When this alert icon appears during operation, it indicates that the LED is shorted or open. Please check if the LED light source is lit normally. If you cannot solve the problem, please contact the company in time. *If some kinds of device encountered the problem on this page, it means that the water cooler is not connected or there is something wrong with the water cooler . Please check the external water cooling equipment. If the water cooling should connected to the water cooling machine, the water cooling machine must be turned on first, otherwise an alarm will be given.