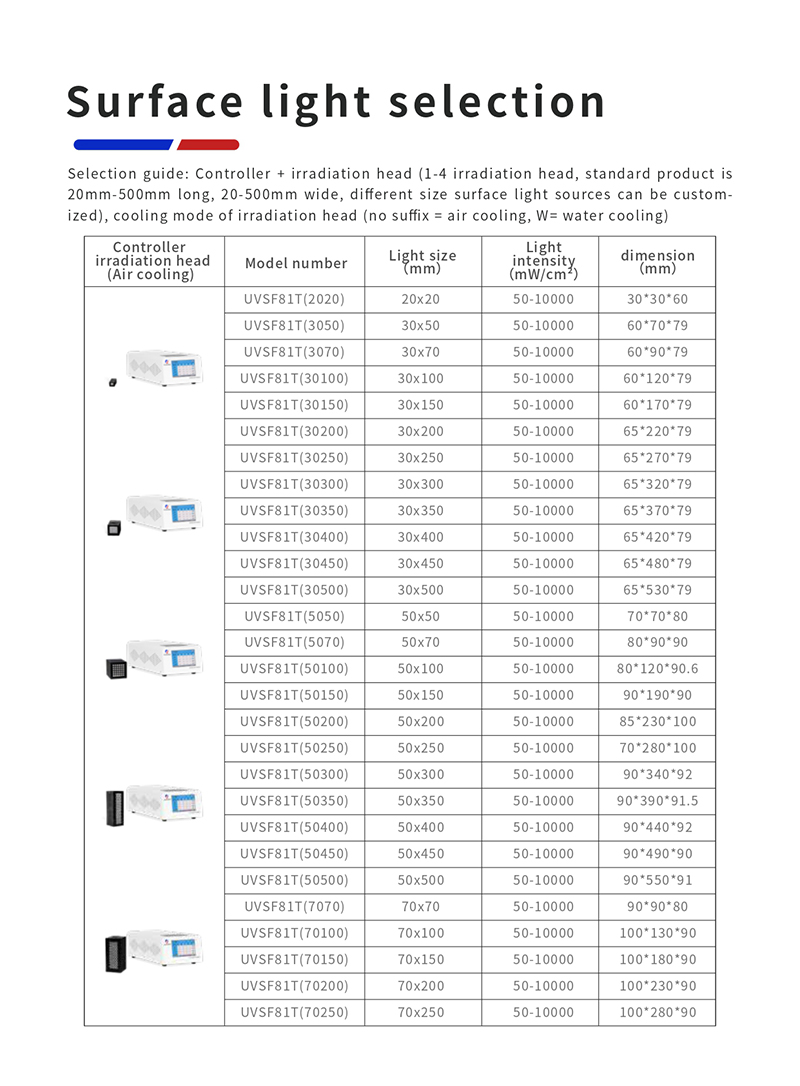

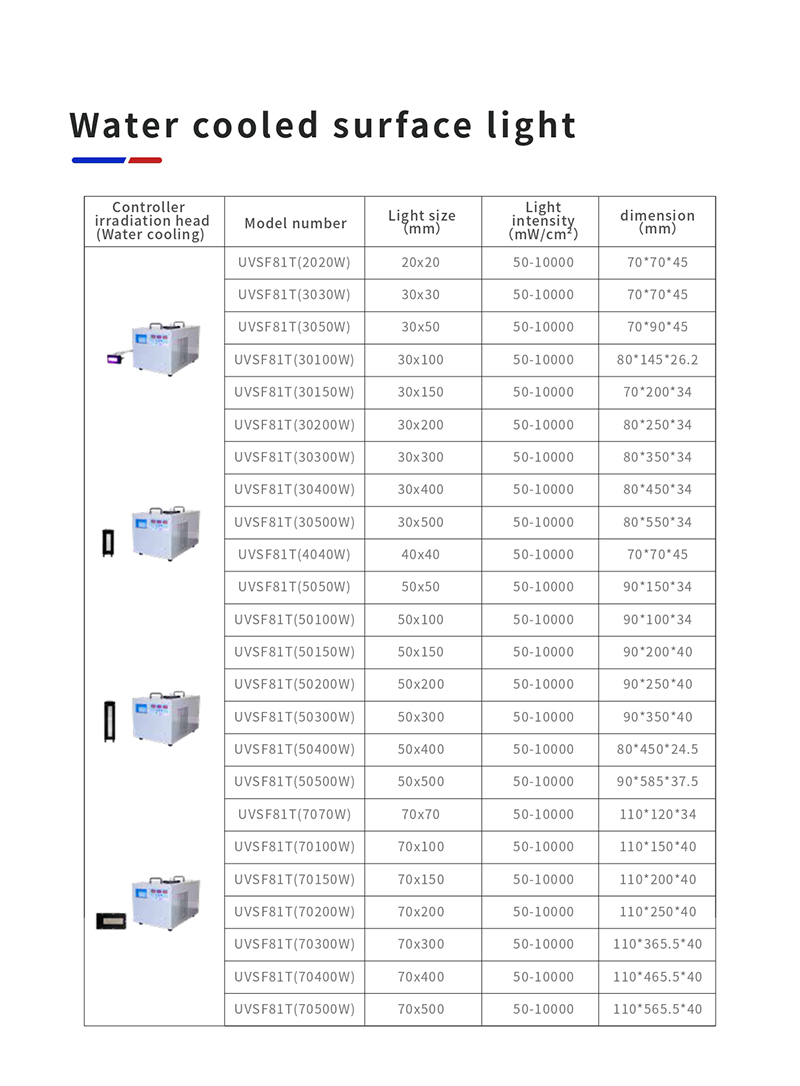

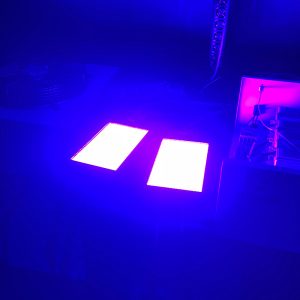

UV LED curing system

230-280nm UVC curing system- WavelengthUVA/UVB/UVC

- ApplicationsUV glue/resin/ink curing

- Luminous size20mm-500mm long, 20-500mm wide

- CoolingFans / Water Cooling

- Light intensity10-10000mW/cm²

Related product literature downloads

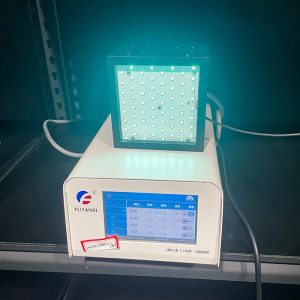

Brief description of UV LED curing system

This UV LED curing system is designed to cure all sides of an object, ensuring thorough and even curing. This is particularly useful for complex shapes and three-dimensional objects.

They produce less heat and consume less power while providing consistent UV output.

UV LED systems can be turned on and off instantly without the need for warm-up or cool-down periods, enhancing productivity and reducing operational downtime.

Common wavelengths include UVA (320-400 nm), UVB (280-320 nm), and UVC (200-280 nm).

LEDs typically have a longer operational lifespan, which means less frequent replacements and lower maintenance costs.

UV LED curing systems do not contain harmful mercury, making them more environmentally friendly and safer for operators.

UV LED curing system Applications

LED UV curing systems can be used for gluing, coating and sterilization, specific applications can be referred to the following:

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

photovoltaic chips, lithium battery module curing;

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

10、sterilization

Use 254nm LED curing system for sterilization.

Product Advantages

1、High power LED beads

Advantages such as high energy, strong light and long service life;

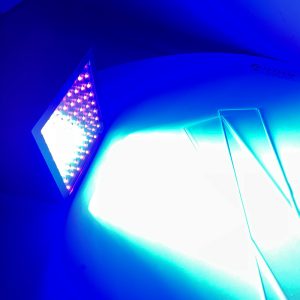

2、Single-band LED ultraviolet light source

common wavelengths of 230nm, 254nm, 270nm, 290nm, 365nm, 385nm, 395nm, 405nm, no thermal radiation;

3, UVLED curing light source without heat radiation

Using high power LED lamp beads, emitting UVA/UVB/UVC light, no infrared wavelength, no thermal radiation;

4、Multi-channel working mode

Standard with a UV LED curing system, according to the actual use of the situation, choose 1-4 irradiation head, no need to repeat the purchase of light source equipment, effective cost savings;

5、Low power consumption

Through the led chip for electrical energy & mdash; & mdash; light energy conversion, less energy loss, low power consumption, about one tenth of the traditional UV mercury lamp, can save a lot of electricity consumption each year;

6、Clean and environmental protection without pollution

Does not contain mercury metal harmful substances, does not produce ozone when used, belongs to a clean and environmentally friendly energy;

7, compact size

UV LED curing system can be customized shape size and irradiation area, suitable for use in different working environments;

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems