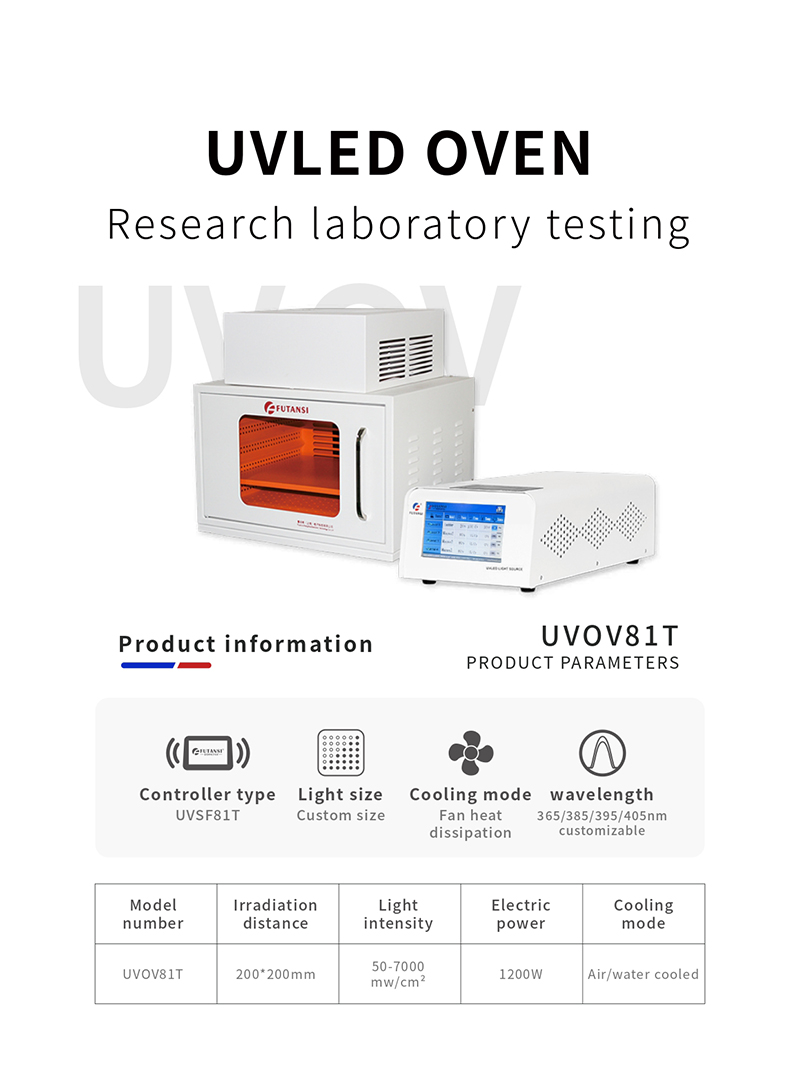

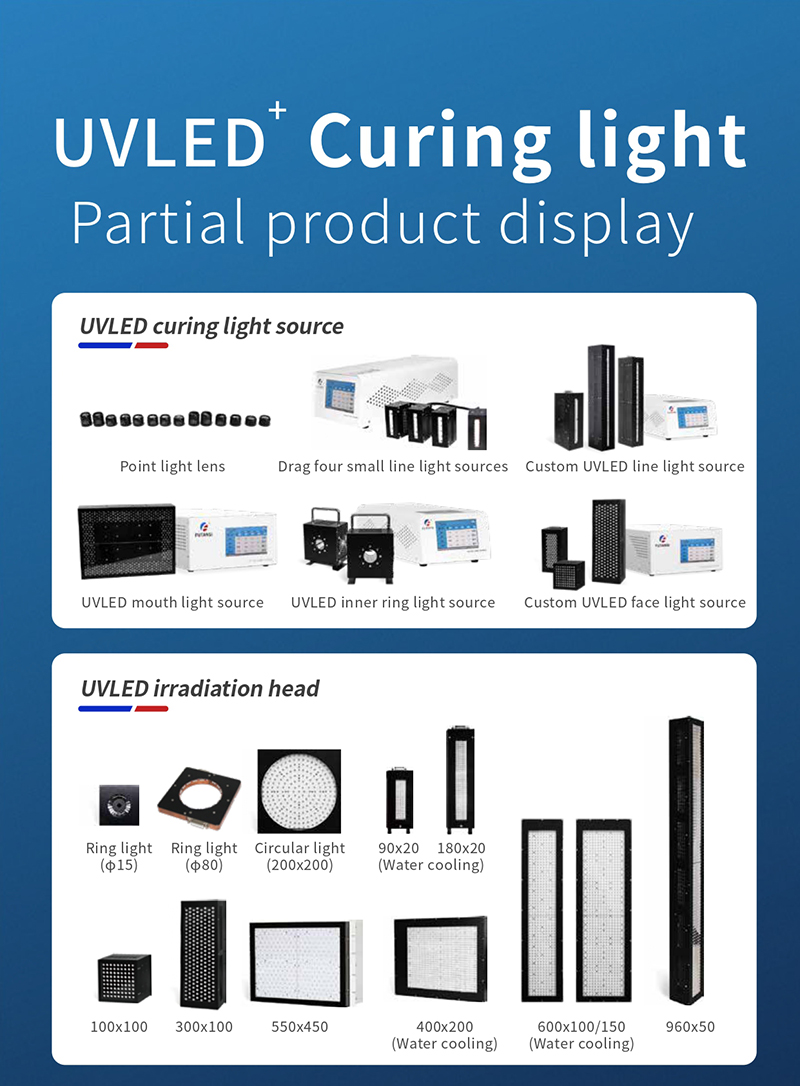

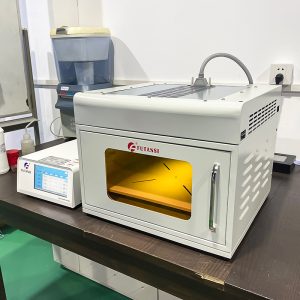

heating UV Curing Oven with LED lights

Nitrogen fillable UV heating Curing Chamber- Wave365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

- Luminous size20mm-500mm long, 20-500mm wide

- CoolingWater Cooling

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of vacuum uv oven

A heating UV oven for curing anaerobic adhesive combines two essential curing methods: heat and UV light. Anaerobic adhesives are typically used in applications where a strong bond is required between metal substrates and where air cannot reach the adhesive to cure it.

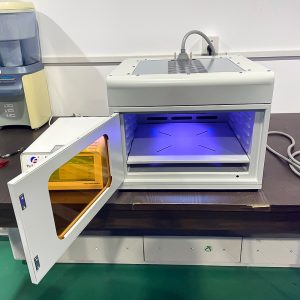

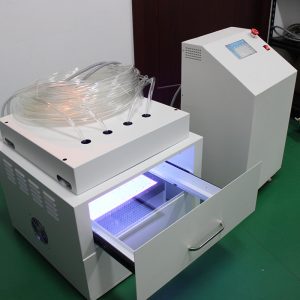

The oven utilizes UV light in the presence of nitrogen within a vacuum-sealed chamber to facilitate the curing process. This controlled environment ensures that the UV-curable materials cure efficiently and uniformly.

The introduction of a nitrogen atmosphere helps to create an oxygen-free environment. This is crucial during the curing process, as oxygen can interfere with the UV curing reactions. The nitrogen atmosphere enhances the efficiency and reliability of the curing process.

The oven is equipped with a vacuum-sealed chamber to remove air and other gases, creating a controlled and stable environment. This vacuum environment aids in preventing oxidation and maintaining consistent curing conditions.

The design of the oven ensures uniform exposure of UV light to the materials being cured. This uniformity is critical for consistent curing results, minimizing variations in the cured material’s properties.

Product Applications

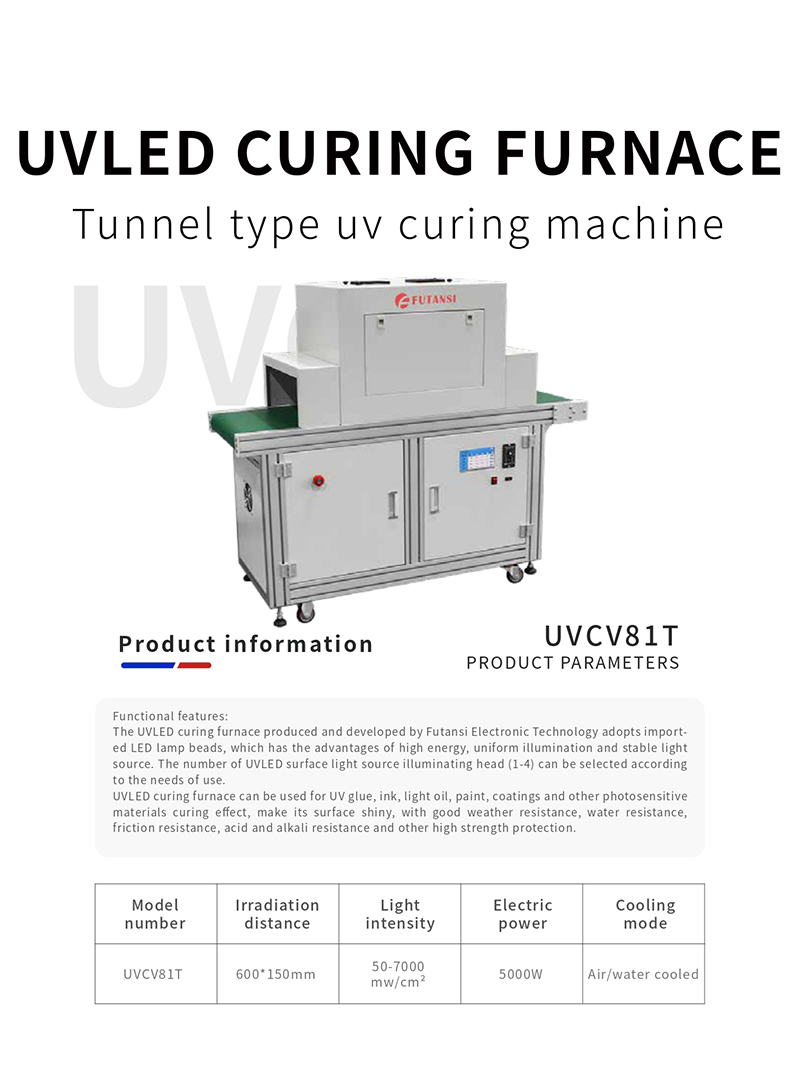

Futansi UV curing ovens can be used for UV glue, ink, varnish, paint, coating and other photosensitive materials curing role, so that its surface glossy and bright, with good weather resistance, water resistance, friction resistance, acid and alkali resistance and other high-intensity protection role. UV curing LED oven chamber application areas are wide, suitable for ink printing, industrial products fixed, specific applications can be referred to the following:

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

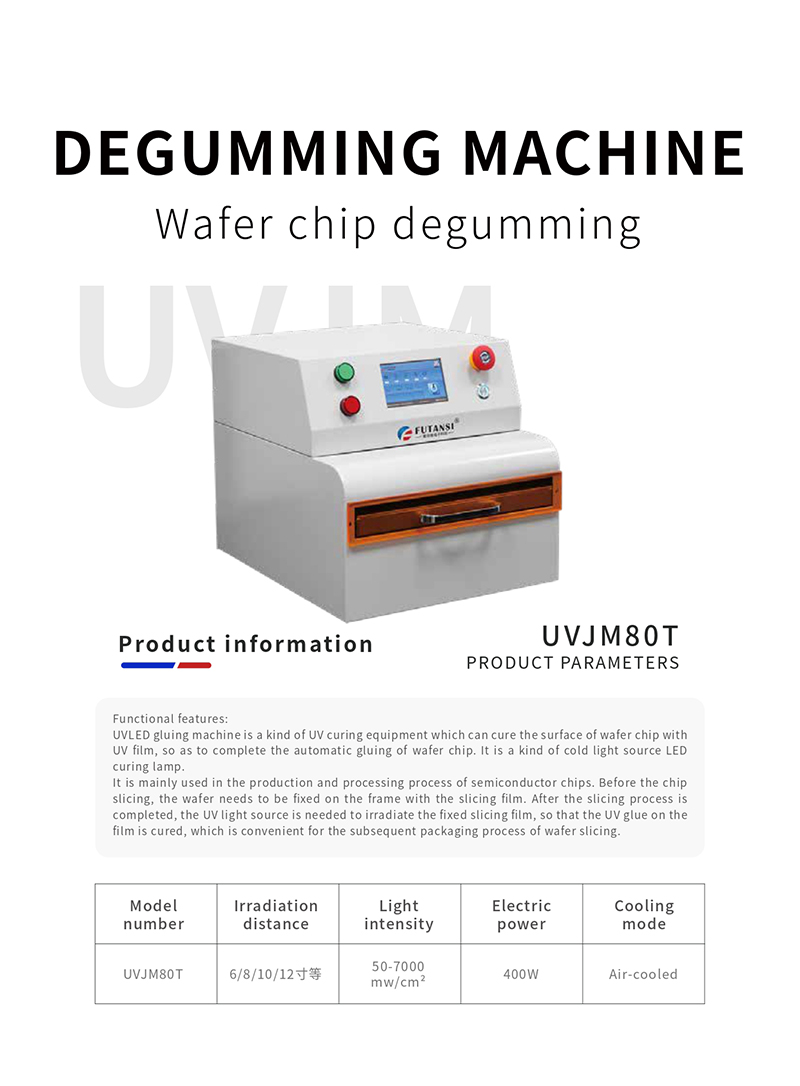

photovoltaic chips, lithium battery module curing;

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

Product Advantages

- Vacuum Chamber: The oven would likely have a vacuum chamber to remove air from the environment. This is crucial for anaerobic adhesives, as they cure in the absence of oxygen.

- Heating Elements: Heating elements inside the oven provide controlled heat to accelerate the curing process. The heat helps to activate the curing agents present in the anaerobic adhesive, promoting faster and more thorough curing.

- UV Lamps: UV lamps emit ultraviolet light, which serves to initiate the curing reaction in the anaerobic adhesive. UV light is commonly used in anaerobic adhesive curing because it can penetrate through the adhesive and activate the curing process without the need for oxygen.

- Control Systems: The oven would likely have sophisticated control systems to monitor and regulate temperature, pressure, and UV exposure time. Precise control ensures that the adhesive is cured effectively without causing damage to the substrates or compromising the integrity of the bond.

- Safety Features: Safety features such as interlocks and protective shielding would be essential to protect operators from exposure to UV light and to prevent accidents during the curing process.

- In summary, a heating UV oven for curing anaerobic adhesive combines heat and UV light to accelerate the curing process in a controlled environment. This ensures strong and reliable bonds between metal substrates in applications where air cannot reach the adhesive.

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)