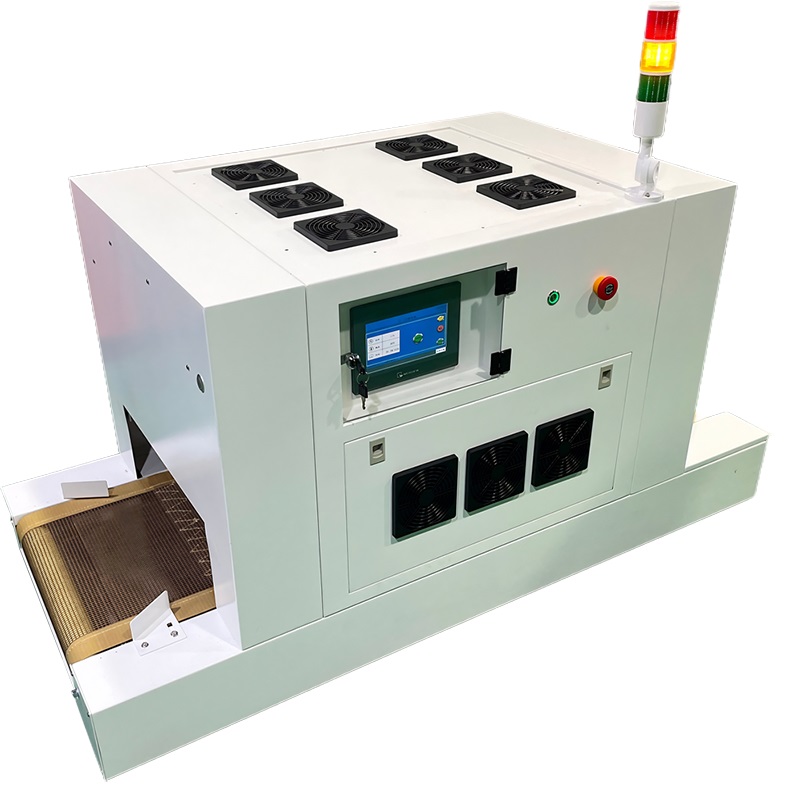

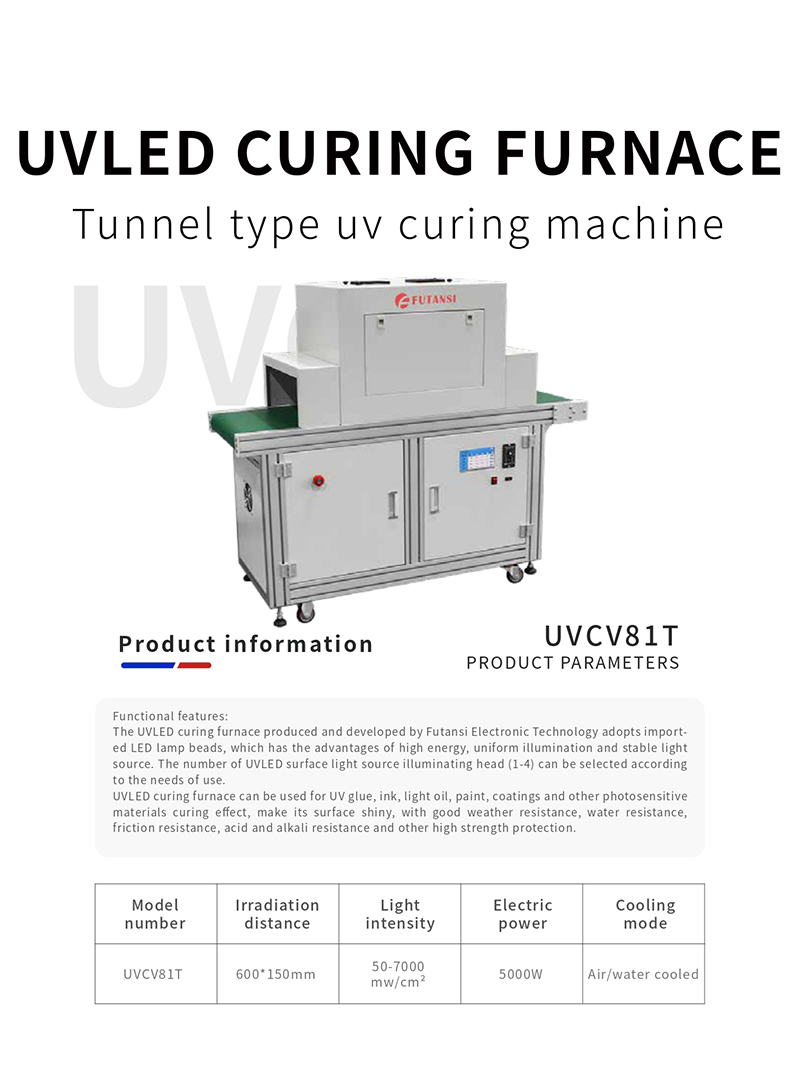

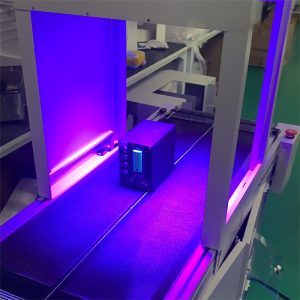

Automated UV curing ovens

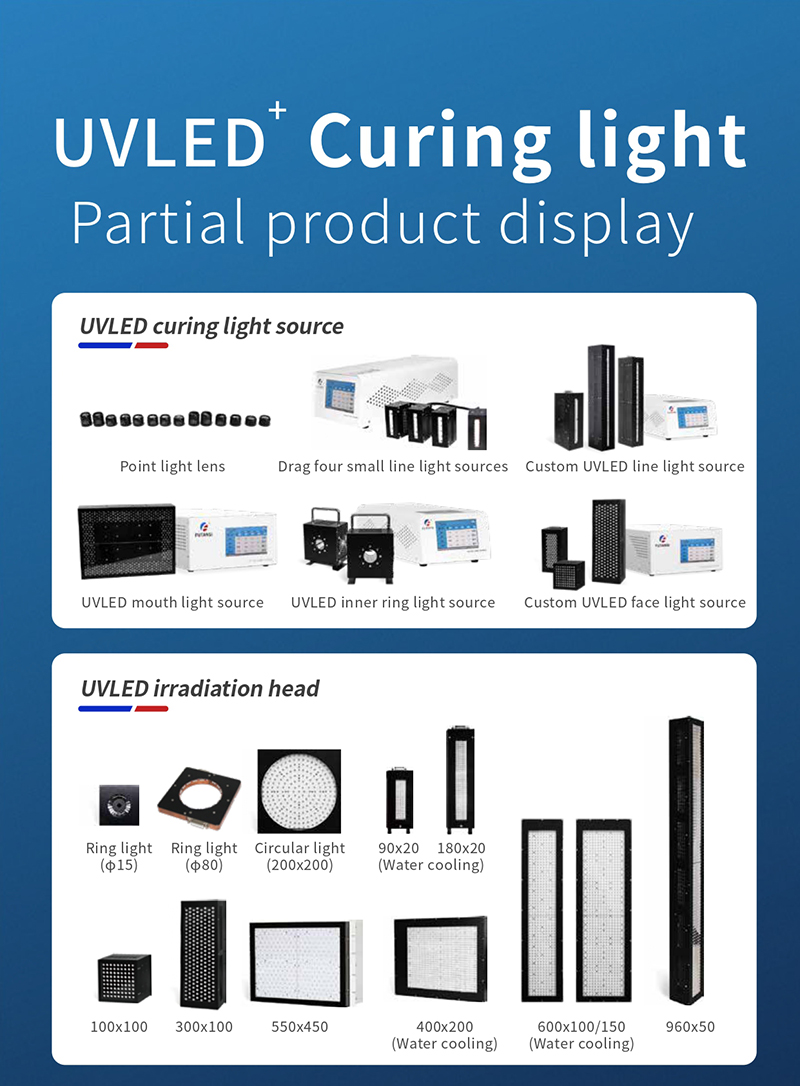

Desktop UV LED curing ovens- Wave365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

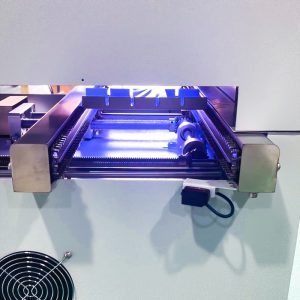

- Luminous size20mm-500mm long, 20-500mm wide

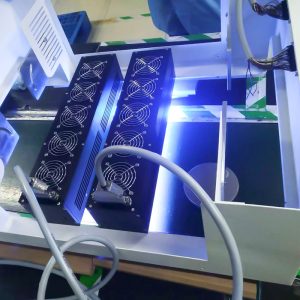

- CoolingFans / Water Cooling

- Light intensity0.5-10W/cm²

Related product literature downloads

Brief description of the product

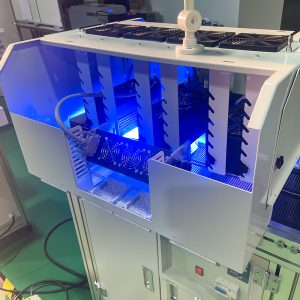

Automated UV curing ovens are a type of equipment that utilises ultraviolet (UV) light sources for curing processes, and are widely used in a variety of industrial manufacturing processes.UV curing technology uses ultraviolet light to irradiate and cause a photochemical reaction with photosensitisers in materials such as coatings, inks, glues, etc., which leads to a rapid curing process. This technology not only improves production efficiency, but also ensures product quality and consistency.

The core components of an automated UV curing oven include UV lamps, reflectors, conveyor belts and control systems, with PLCs (Programmable Logic Controllers) playing a vital role in automated UV curing ovens, where the PLC control system can accurately control parameters such as the switching on and off of the UV lamps, conveyor belt speeds and temperatures, thus enabling fully automated operation. This not only reduces manual intervention, but also improves production stability and safety.

Product Applications

UV curing ovens are widely used in the following fields:

Electronics manufacturing: UV curing oven is widely used in the encapsulation and protection of electronic components. It can quickly cure electronic glue to ensure the stability and reliability of components.

Printing industry: UV curing technology is widely used in the printing industry, especially in the curing process of UV ink. It provides high-quality printing results and dries quickly, making it suitable for high-speed printing.

Automotive Manufacturing: In the automotive manufacturing process, UV curing ovens are used for painting and bonding of lamps, interior parts and other components. It can provide high strength bonding effect and good weather resistance.

Medical Devices: UV curing ovens are used for bonding and coating processes in the manufacturing of medical devices. It provides a sterile, non-toxic cure that meets the stringent requirements of medical devices.

Product Advantages

Advantages of UV curing oven

Energy efficient: UV curing ovens cure very quickly, usually only a few seconds to a few minutes to complete the curing process. This greatly reduces the production cycle and improves productivity. In addition, the energy consumption of UV curing oven is relatively low, energy saving effect is remarkable.

Environmentally friendly and non-polluting: UV curing technology does not require the use of solvents, and therefore does not produce harmful gases and wastewater, in line with environmental requirements. This is especially important for those industries that have strict requirements for environmental protection.

High-quality curing: UV curing oven can provide uniform UV irradiation to ensure the consistency of curing effect. The cured products have excellent physical properties such as high hardness, high abrasion resistance and good adhesion.

Flexible: UV curing oven can adapt to different production needs, whether it is small batch production or large-scale production, can be flexible to cope with. In addition, the UV curing oven can be adjusted to different materials and process requirements, with strong adaptability.

| NO. | Parts | Items | Technique Data |

| 1 | Controller UVSF81T | Voltage | 220V |

| 2 | MODEL SIZE | Built in pipeline | |

| 3 | Cooling mode | Air-Cooled | |

| 4 | Control Method | On-screen touch/pedal /RS232/485 communication | |

| 5 | Adjustable range of irradiationpower | 10%-100% adjustable | |

| 6 | irradiation swelling model | Manual: Steady on after startup | |

| 7 | Automatic: Set irradiation countdown time (0.1-999.9s) | ||

| 8 | Step: Achieve step irradiation (1-20 steps) | ||

| 9 | Loop ladder: single/infinite | ||

| 10 | traffic control | RS232 serial port, 485: data read and write, LED switchand parameter control | |

| 11 | I\O interface LED switch control and running stateoutput | ||

| 12 | Irradiation head SFHD-300150 | heat-dissipating method | air cooling |

| 13 | wavelength coverage | 365±5nm | |

| 14 | External structural dimension | 650X120X72mm | |

| 15 | Light point size | 600x40mm | |

| 16 | Suggested range | 15-20 (mm) | |

| 17 | exposure intensity (MAX) | 1000 mw/c ㎡(FTIU500 Illuminometer measurement data) | |

| 18 | Uniformity of irradiation intensity | 10%, homogeneity=( (Max-Min)/(Max +Min)×100% ) | |

| 19 | working life | 20000 hour (Constant temperature 20±1℃, constanthumidity 50±3%, attenuation about 25%) | |

| 20 | power cord | cable | 2m |

| 21 | connecting line | cable | 2m |

| 22 | Shading box | External structural dimension | 800X850X350 |

| 23 | assembly line | External structural dimension | 1500X850X750 |

| 24 | Water cooler (9500) | External structural dimension | 1300X1190X680 |

| 25 | electric power | Total electrical power of eachcomponent | 1600w |

| 26 | Optional functions | on-line monitoring | No |

| 27 | Optional functions | Radiosity | No |

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-拷贝-300x300.jpg)

-拷贝-300x300.jpg)

-拷贝-300x300.jpg)