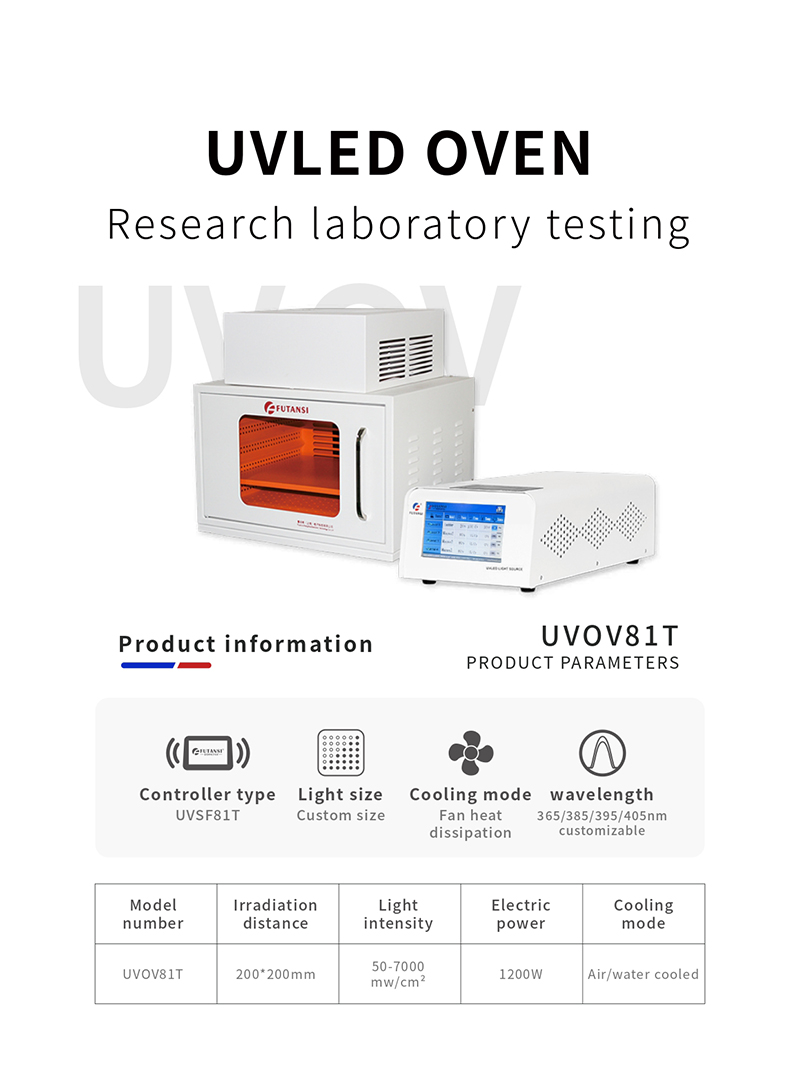

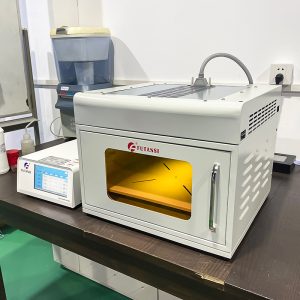

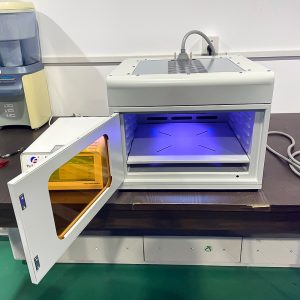

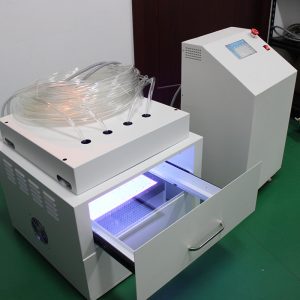

UV Curing Oven with LED curing light 200x200mm

UV Oven Chambers- Wave365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

- Luminous size20mm-500mm long, 20-500mm wide

- CoolingFans Cooling

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of the product

An LED UV oven is a type of curing equipment used in various industries, particularly in printing, coating, and electronics manufacturing. UV (ultraviolet) curing is a process where ultraviolet light is used to initiate a photochemical reaction, causing a liquid or resin to harden or cure into a solid form. LED UV ovens specifically use light-emitting diodes (LEDs) to emit UV light for curing purposes.

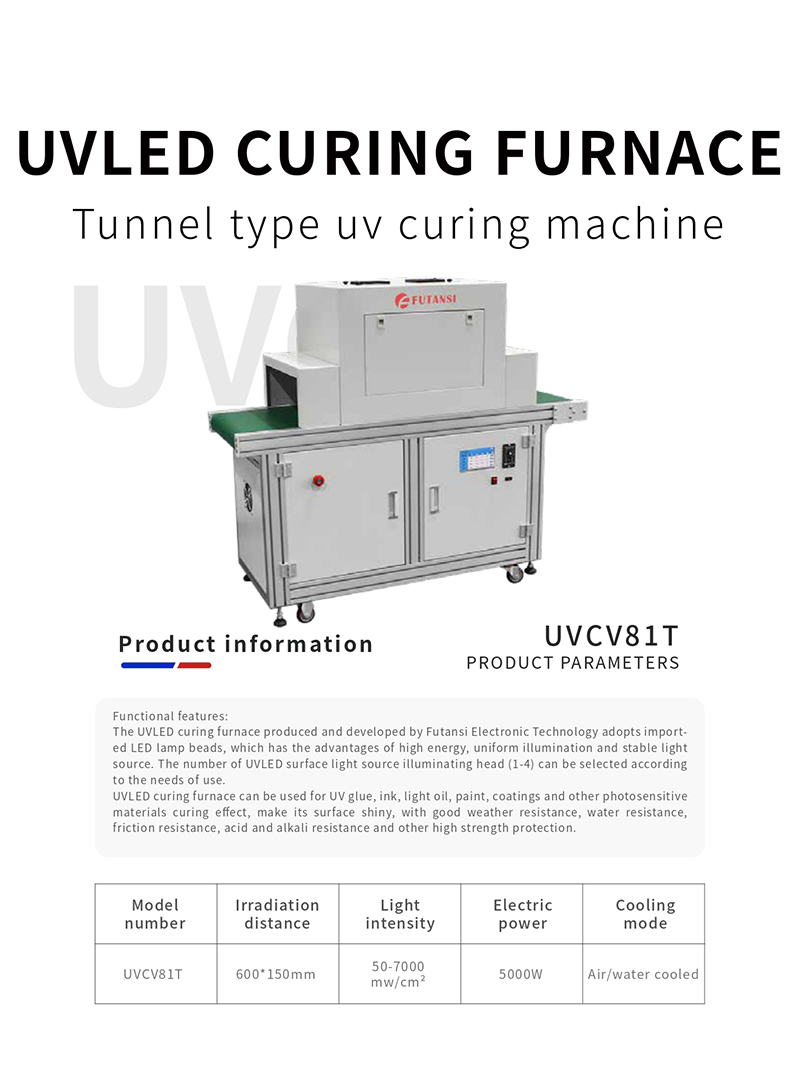

Futansi electronic technology production and development of UV light-curing equipment, using high quality LED lamp beads, with high energy, uniform light, light source stability and other advantages.

UV LED oven using touch screen control mode, power adjustable (10%-100%), can freely set the irradiation time. The equipment is small in size, covers an area of less, easy to install, and can be used with the assembly line workshop.

Product Applications

Futansi UV oven can be used for UV glue, ink, varnish, paint, coating and other photosensitive materials curing role, so that its surface glossy and bright, with good weather resistance, water resistance, friction resistance, acid and alkali resistance and other high-intensity protection role. UV curing LED oven chamber application areas are wide, suitable for ink printing, industrial products fixed, specific applications can be referred to the following:

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

photovoltaic chips, lithium battery module curing;

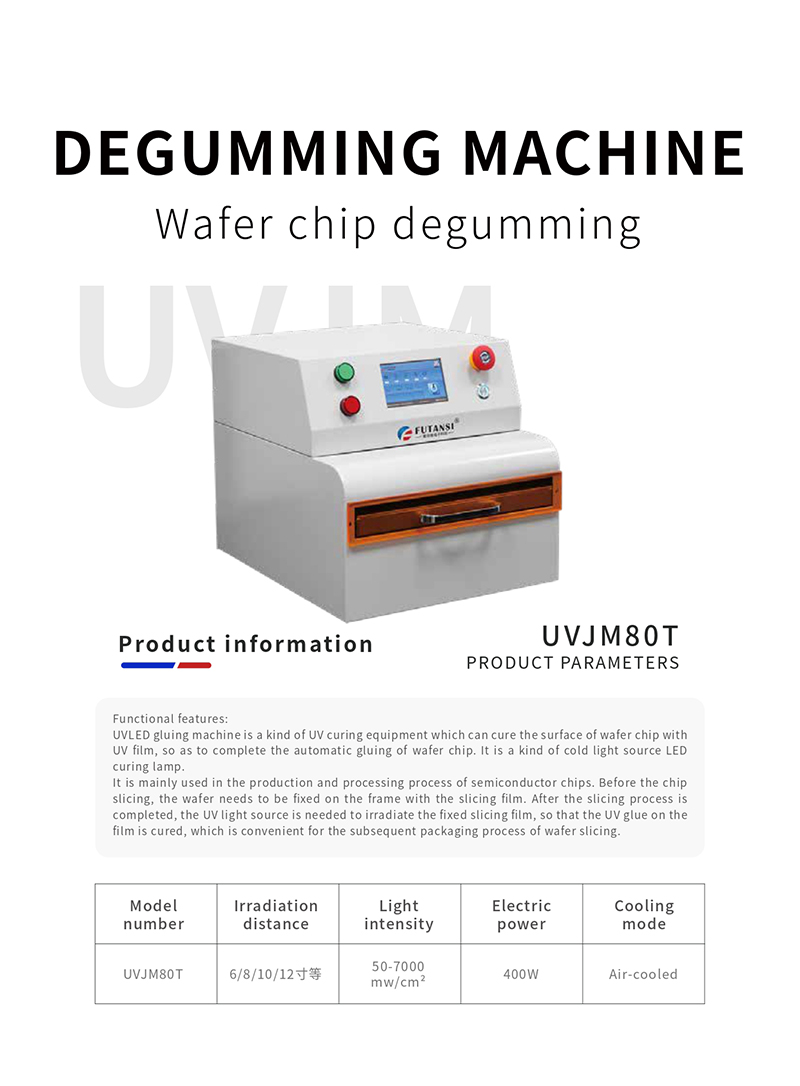

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

Product Advantages

- Energy Efficiency: LED UV ovens consume less energy compared to traditional UV curing systems, making them more environmentally friendly and cost-effective to operate.

- Instant On/Off: LED UV lamps can be turned on and off instantly, eliminating the warm-up and cool-down times associated with traditional UV lamps. This feature helps to increase productivity and reduce downtime.

- Longevity: LED UV lamps have a longer lifespan than traditional UV lamps, reducing maintenance costs and downtime for lamp replacement.

- Cooler Operation: LED UV lamps emit less heat compared to traditional UV lamps, which can be beneficial for heat-sensitive substrates and materials.

- Precise Control: LED UV ovens offer precise control over curing parameters such as intensity and exposure time, allowing for consistent and repeatable curing results.

- Environmentally Friendly: LED UV curing systems typically do not emit ozone or mercury, making them safer for the environment and workplace.

- Versatility: LED UV ovens can be used for curing a wide range of materials, including inks, coatings, adhesives, and encapsulants, on various substrates such as paper, plastic, glass, and metal.

- Compact Design: LED UV ovens often have a more compact footprint compared to traditional UV curing systems, making them suitable for installations where space is limited.

| NO. | Parts | Items | Technique Data |

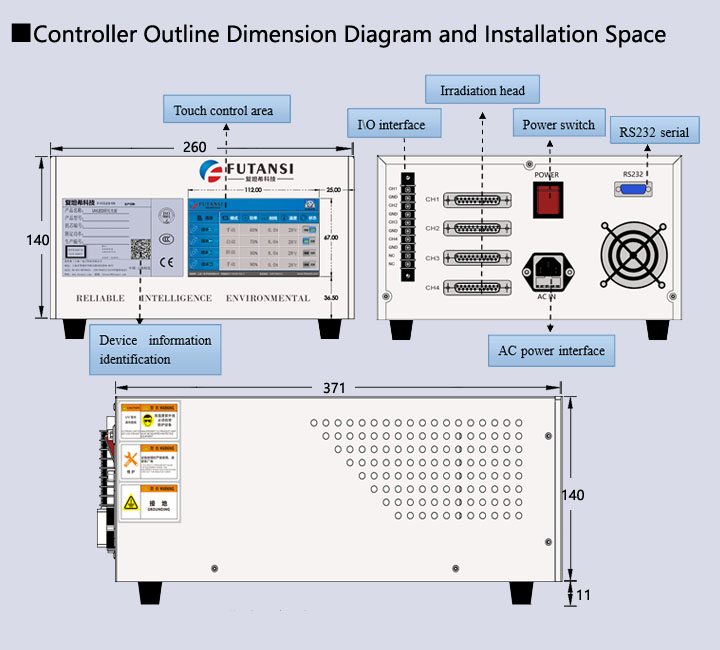

| 1 | Controller UVSF81T | Voltage | 220V |

| 2 | MODEL SIZE | 412X264X142(mm) | |

| 3 | Cooling mode | Air-Cooled | |

| 4 | Control Method | On-screen touch/pedal /RS232/485 communication | |

| 5 | Adjustable range of irradiationpower | 10%-100% adjustable | |

| 6 | irradiation swelling model | Manual: Steady on after startup | |

| 7 | Automatic: Set irradiation countdown time (0.1-999.9s) | ||

| 8 | Step: Achieve step irradiation (1-20 steps) | ||

| 9 | Loop ladder: single/infinite | ||

| 10 | traffic control | RS232 serial port, 485: data read and write, LED switchand parameter control | |

| 11 | I\O interface LED switch control and running stateoutput | ||

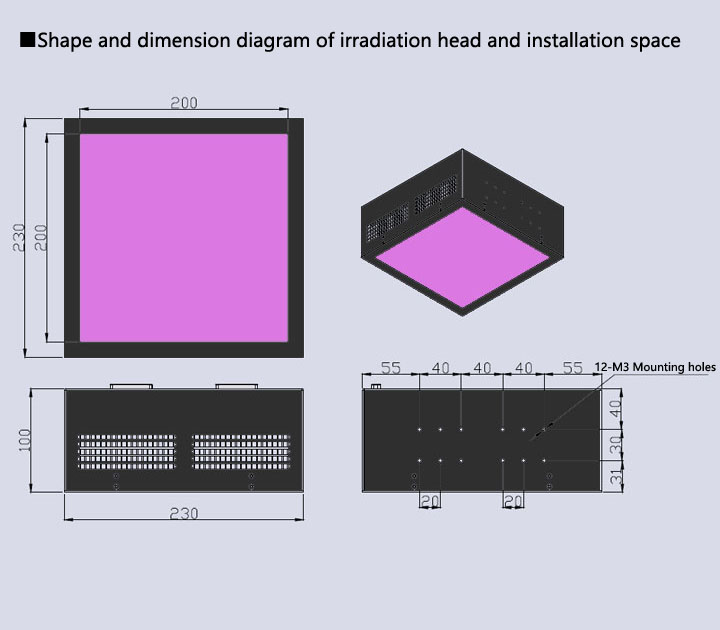

| 12 | Irradiation headSFHD-200200 | heat-dissipating method | air cooling |

| 13 | wavelength coverage | 365±5nm | |

| 14 | External structural dimension | 230*230*100mm | |

| 15 | Light point size | 200x200mm | |

| 16 | Suggested range | 15-20 (mm) | |

| 17 | exposure intensity (MAX) | 1000 mw/c ㎡ or customized | |

| 18 | Uniformity of irradiation intensity | 10%, homogeneity=( (Max-Min)/(Max +Min)×100% ) | |

| 19 | working life | 20000 hour (Constant temperature 20±1℃, constanthumidity 50±3%, attenuation about 25%) | |

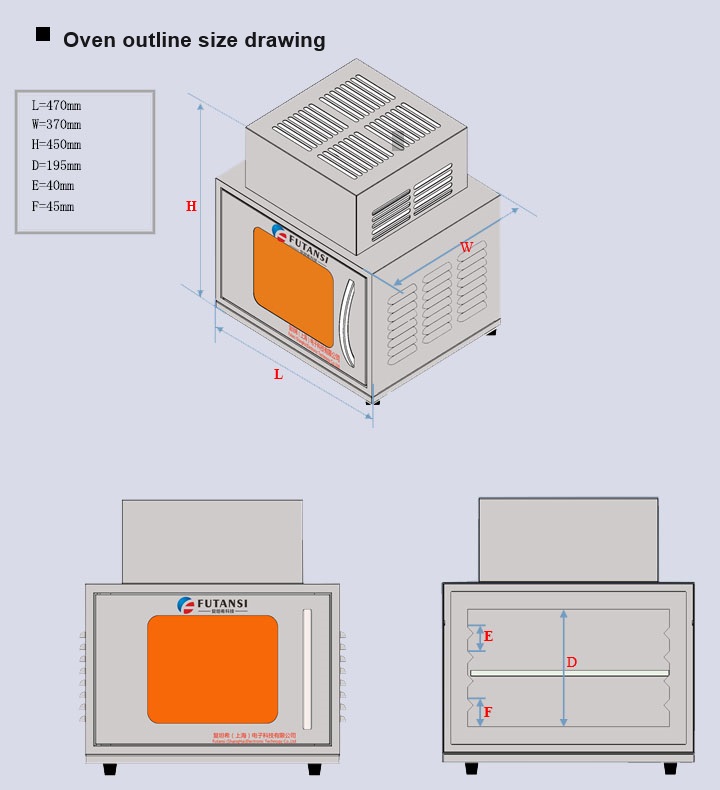

| 20 | Curing Oven | Overall dimensions | 450X450X370 mm |

| 21 | Product placement size | 360X310 mm(Width x DEEP) | |

| 22 | power cord | cable | 2m |

| 23 | connecting line | cable | 2m |

| 24 | electric power | Total electrical power of eachcomponent | 1300w |

| 25 | Optional functions | on-line monitoring | None |

| 26 | Optional functions | Radiosity | None |

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

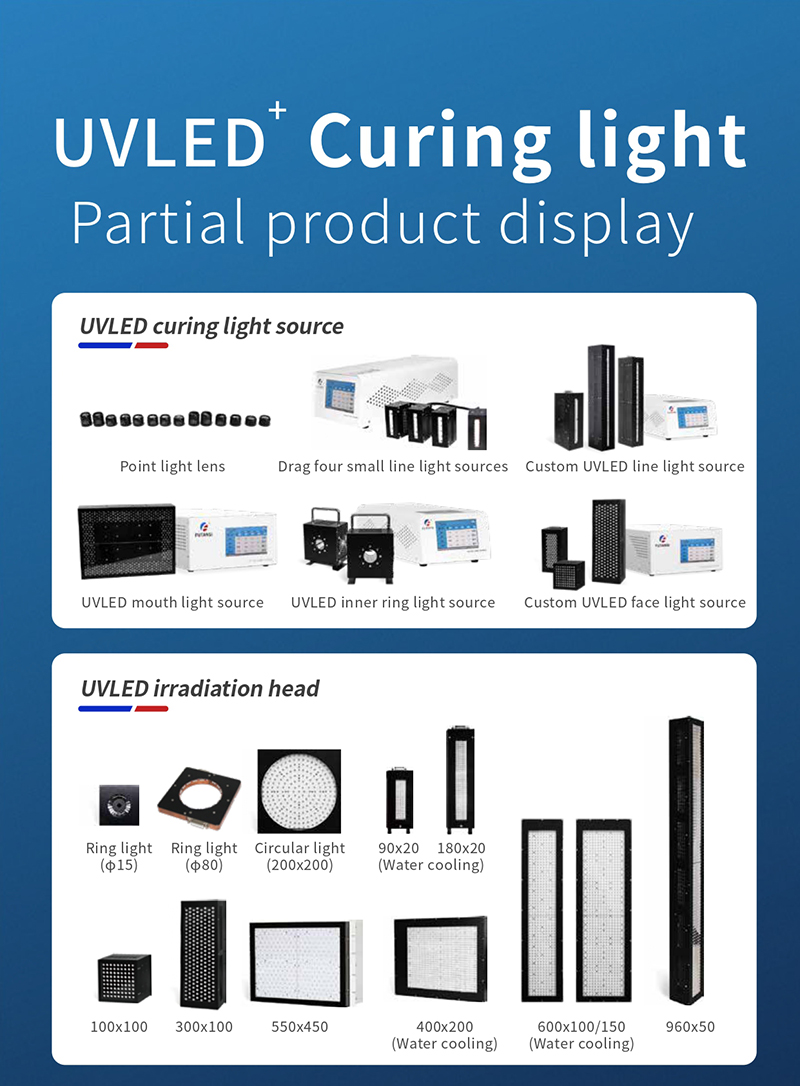

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)