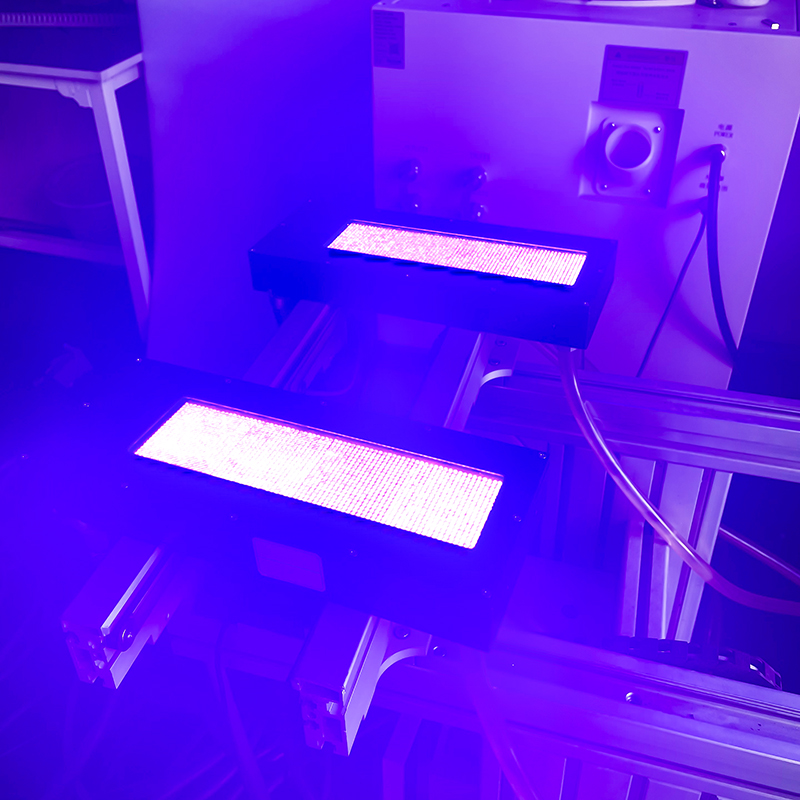

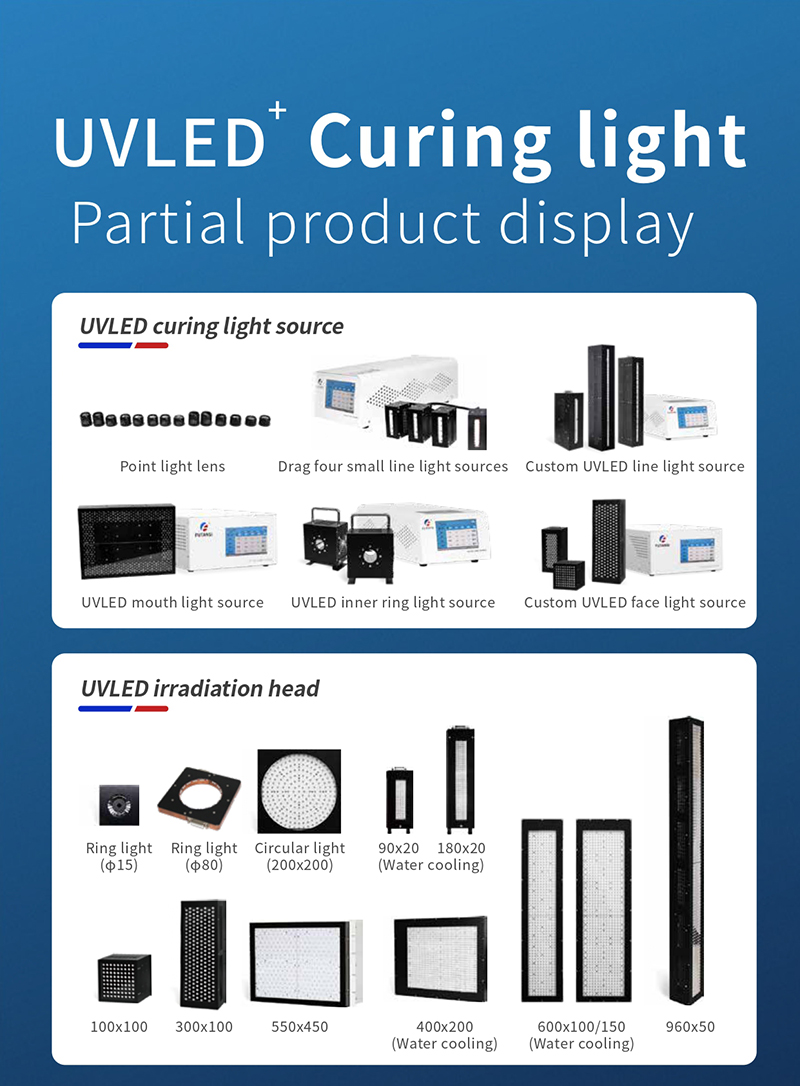

LED water-cooled large UV Area light source

large size LED UV curing systems- Wavelength365/385/395/405nm(Customised)

- ApplicationsUV adhesive/resin/ink curing

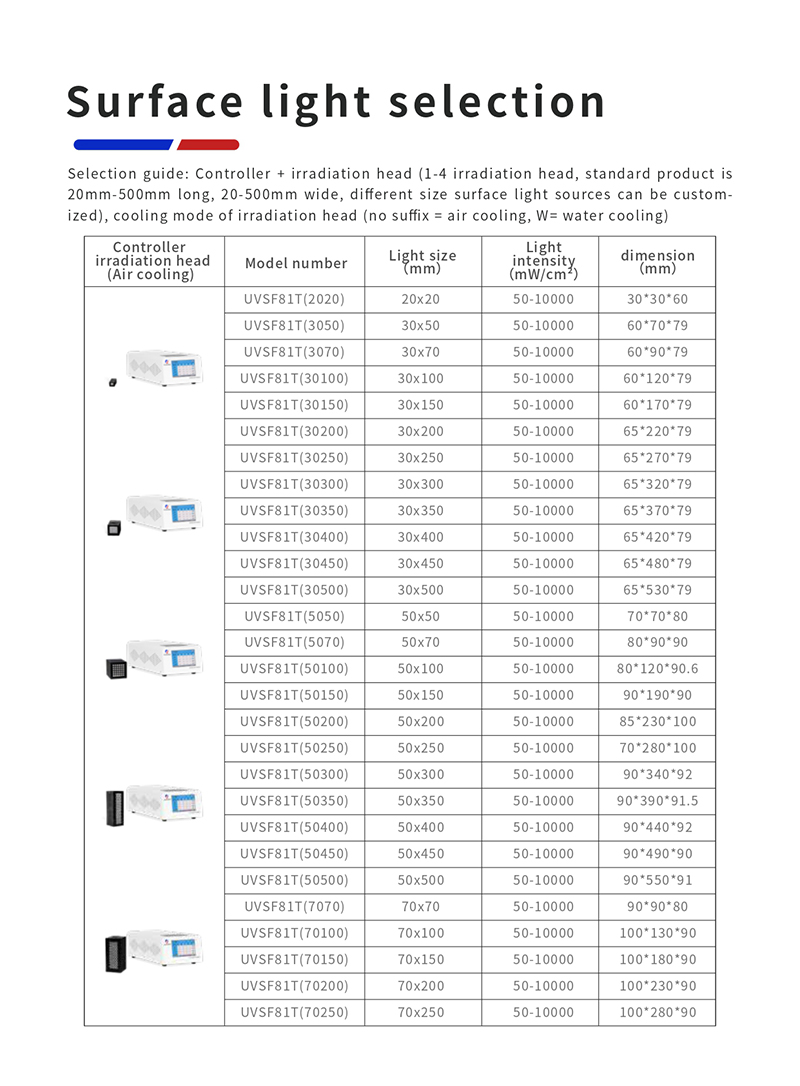

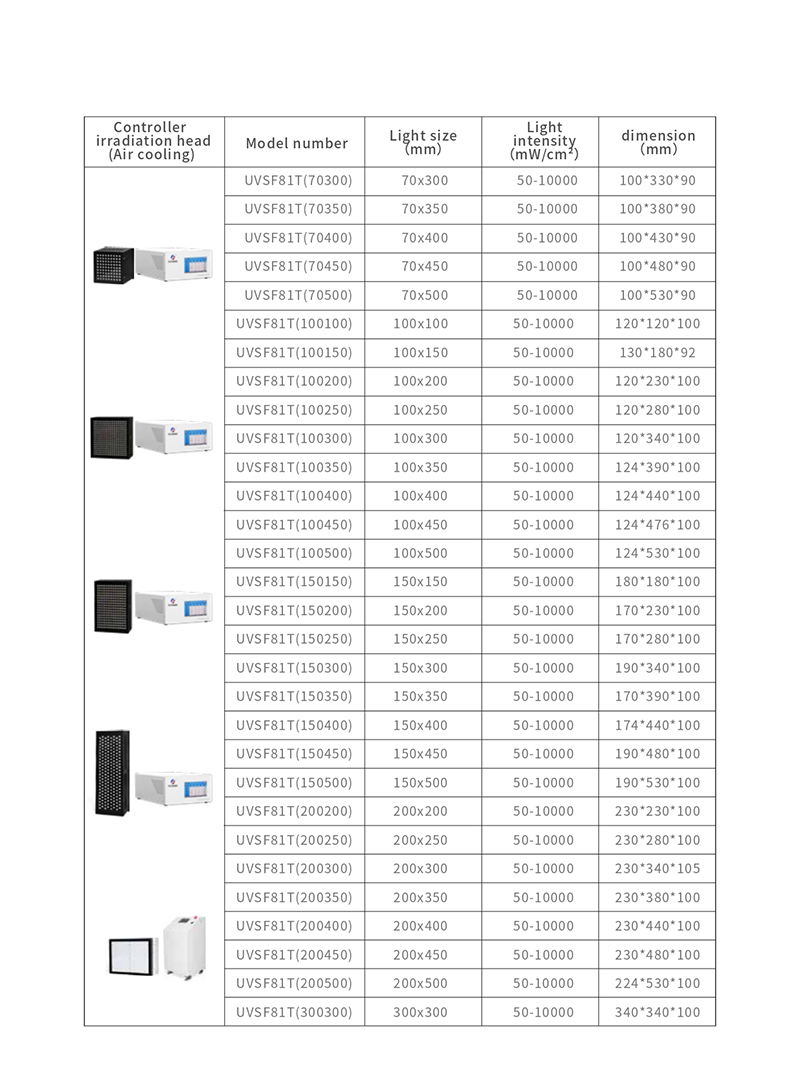

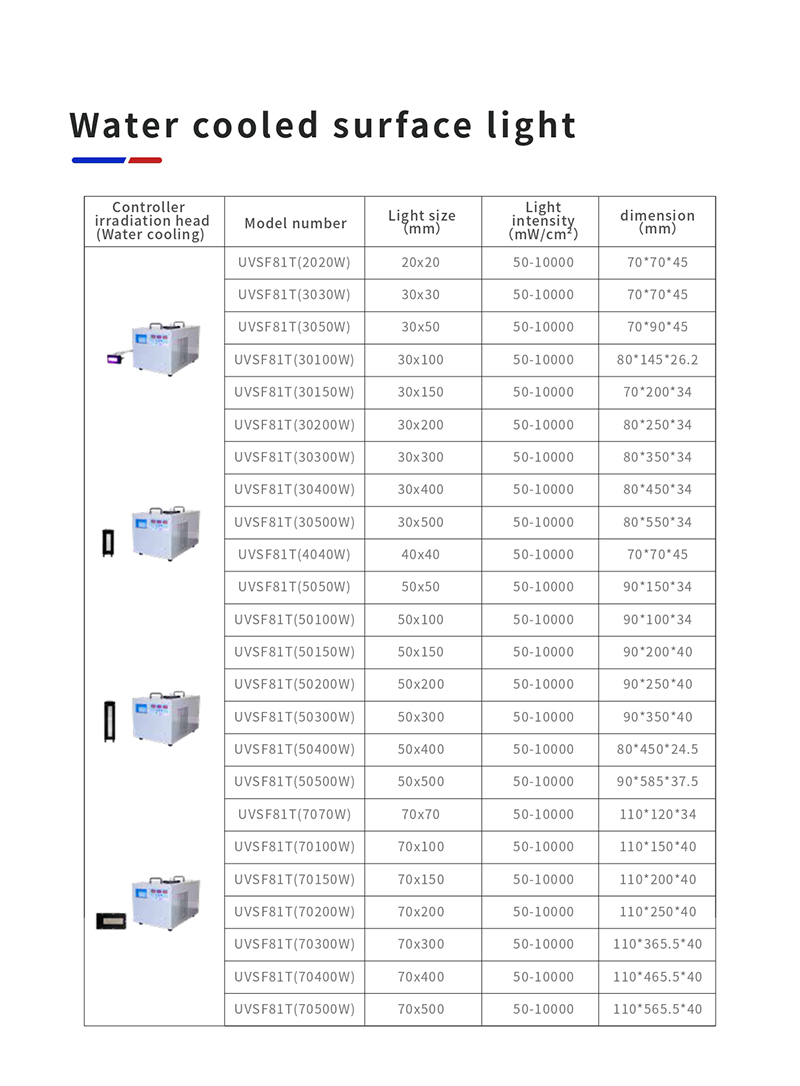

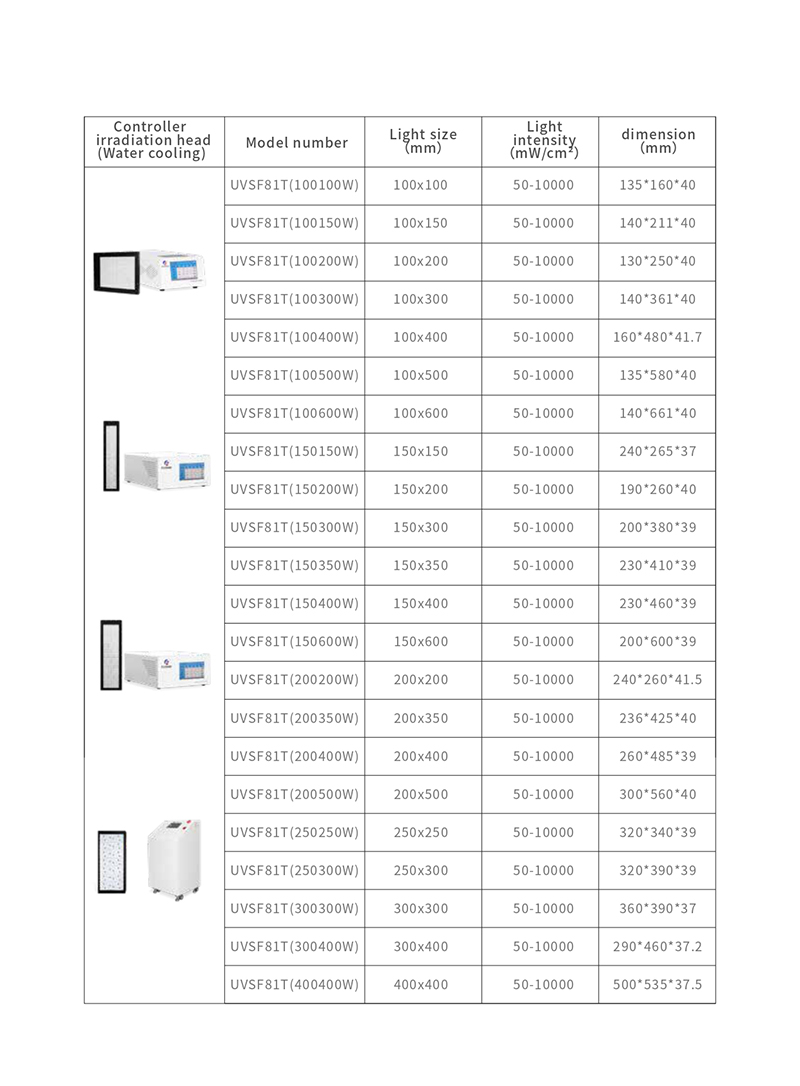

- Luminous size20mm-500mm long, 20-500mm wide

- Cooling methodFans / Water Cooling

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of the product

In the ever-evolving landscape of UV curing systems, water-cooled large size UV curing systems emerge as a technological breakthrough, offering enhanced efficiency and performance. This article delves into the key features, applications, and advantages of these systems, showcasing their potential to transform various industries.

Product Applications

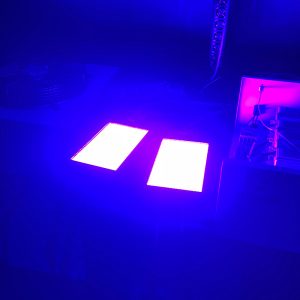

Futansi UVLED Area Curing Systems can be used for UV adhesive, UV ink, UV varnish, UV paint, UV coating and other photosensitive materials cure, so its surface glossy and bright, with good weather resistance, water resistance, friction resistance, acid and alkali resistance and other high-intensity protection role. led uv light source application areas are wide, suitable for ink printing, industrial products fixed, specific applications can be referred to the following:

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

photovoltaic chips, lithium battery module curing;

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

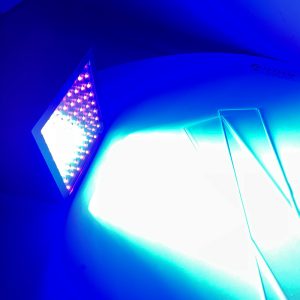

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

10、ink printing

screen printing label printing.

Product Advantages

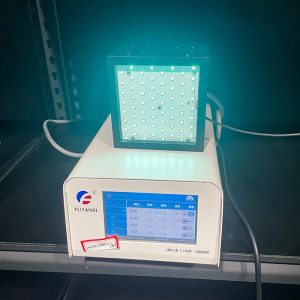

- Water Cooling Mechanism: Unlike air-cooled systems, water-cooled UV curing systems utilize water as a cooling medium to dissipate heat generated during the curing process. This mechanism ensures consistent and optimal operating temperatures, enhancing the overall efficiency of the system.

- Large Size Configuration: Designed for applications requiring a substantial curing area, these systems boast a large size configuration, making them ideal for industrial-scale processes.

B. Advantages of Water-Cooled Systems

- Temperature Control: The water-cooling feature allows precise temperature control, preventing overheating and ensuring uniform curing across the entire surface.

- Extended Lamp Life: By maintaining a stable operating temperature, water-cooled systems contribute to the extended life of UV lamps, reducing the frequency of replacements and associated downtime.

Advantages for Industrial Operations

A. Enhanced Productivity and Throughput

- Continuous Operation: The water-cooled system allows for continuous operation without the need for frequent pauses to cool down, maximizing productivity in industrial settings.

- Large Batch Processing: Industries dealing with large batches of products benefit from the expansive curing area, facilitating the simultaneous processing of multiple items.

B. Cost-Efficiency and Sustainability

- Energy Efficiency: The precise temperature control not only enhances curing but also contributes to energy efficiency, reducing overall operational costs.

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems