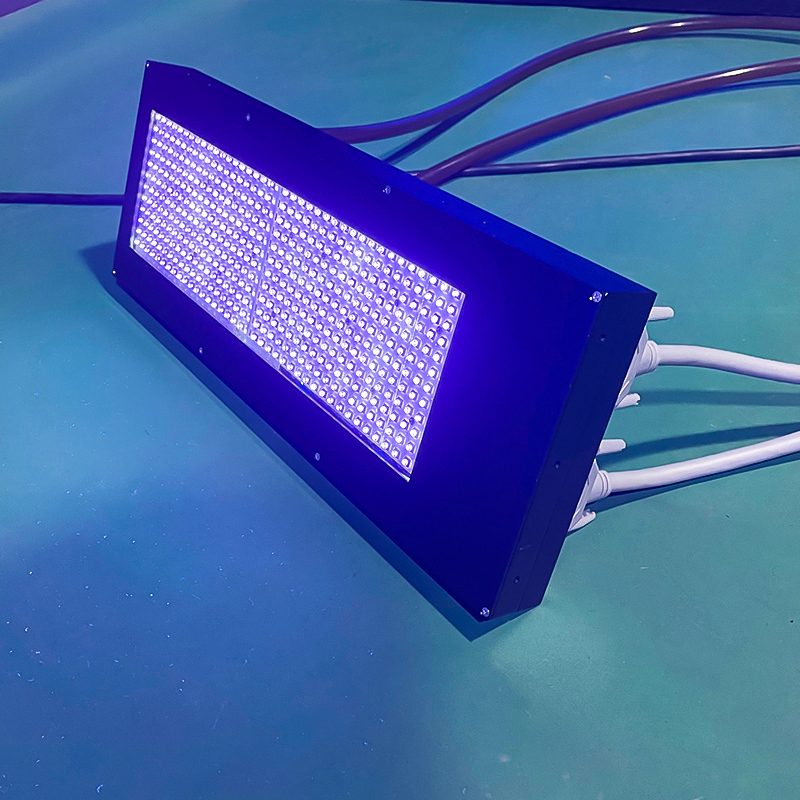

High Power UV LED Curing Systems 200x200mm

2300High power UV LED curing systems with a 200x200mm curing area are ideal for large-scale industrial applications, providing fast and efficient curing for a range of materials.

View detailsSearch the whole station

Fan cooling and water cooling are two common methods used for cooling UV curing machines, including UV lamps in UV curing systems. Each method has its advantages, and the choice between them depends on specific requirements and preferences. Here’s a comparison of the advantages of fan cooling and water cooling in UV curing machines:

Fan Cooling UV Curing Machine:

Water Cooling UV Curing Machine:

In summary, the choice between fan cooling and water cooling for UV curing machines depends on factors such as the intensity of UV curing requirements, temperature sensitivity of materials, cost considerations, and infrastructure requirements. Fan cooling is often suitable for simpler and lower-intensity applications, while water cooling is preferred for high-intensity applications where precise temperature control and heat dissipation are critical.

Our application engineering experts will be on site to answer questions about uv-curing systems, and provide demonstrations of our products and technologies.

Send us an email or visit the Futansi website and learn more about our latest products now.

High power UV LED curing systems with a 200x200mm curing area are ideal for large-scale industrial applications, providing fast and efficient curing for a range of materials.

View detailsUV curing is a process widely employed in producing passive optical devices such as waveguides, lenses, and optical fibers. It involves the use of UV light to initiate a photochemical reaction in photosensitive materials, transforming them from a ...

View detailsUVLED Curing Systems: Applications in Glass Products

View details

HelloPlease log in