Water-cooled compact UV LED Area light source

2156Water-cooled compact UV LED area light sources are essential tools in industrial applications, providing fast and efficient curing for a range of materials.

View detailsSearch the whole station

In their search for optimal UV curing systems, engineers tend to consult product technicalities such as light intensity, covered curing area, and the expected longevity of the system to inform their selection. However, an often neglected yet pivotal parameter is the ‘working distance’—the gap between the UV light source and the target material undergoing curing.

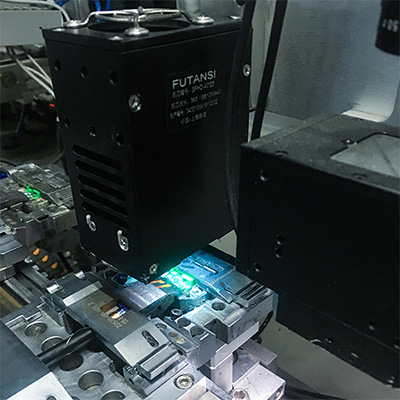

A Futansi UV curing equipment effectively cures a printed circuit board.

The necessary cumulative UV exposure for proper curing is generally calculated using the formula:

Cumulative UV Exposure = Intensity × Exposure Time

Product specifications commonly list light intensity levels to assist in approximating the time it takes to cure. Nonetheless, these specifications might overlook the disclosure of the exact working distance for these intensity readings.

The significance of working distance can’t be overstressed as it directly influences how much light intensity reaches the material, which can drastically differ among UV sources that appear similar. The focus and spread of the beam from the emitter can vary the curing effect at different distances. For instance, with high-speed printing that positions materials very close to the UV source, the need for precision in focus may be reduced. Conversely, when curing adhesives on a PCB that has components of varying heights, a more narrowly focused light is preferable.

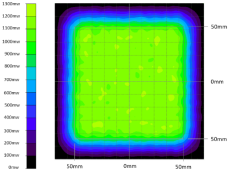

Uniformity of the emitted light across the curing surface is another factor impacting the efficiency of a UV curing equipment. Data sheets may highlight peak intensity values at the center of the irradiation field; however, the actual light distribution rarely achieves this uniformity throughout, which can compromise curing quality for items positioned away from the center.

The Necessity for Practical Testing Data sheets are informative, but they don’t convey the complete operational picture. Process engineers are encouraged to conduct practical tests to gauge how a UV flood systems performs with their specific materials and formulations. Such empirical testing helps refine accurate exposure duration settings, leading to a dependable curing process.

In conclusion, when evaluating uv led light source, it is imperative that engineers consider more than just the datasheet details. Factors like working distance, emitter focus, and uniformity are crucial and warrant thorough understanding and testing to ensure successful curing outcomes.

Water-cooled compact UV LED area light sources are essential tools in industrial applications, providing fast and efficient curing for a range of materials.

View detailsThe UVLED curing machine utilizes ultraviolet (UV) LED light source to quickly cure adhesives or coatings, enabling efficient production and assembly in the automotive manufacturing process.

View detailsOne of the standout features of 6-axis stages is their ability to be tailored to the specific needs of various industries. The customization options available ensure that these stages seamlessly integrate into different production processes

View detailsUV curing is a process widely employed in producing passive optical devices such as waveguides, lenses, and optical fibers. It involves the use of UV light to initiate a photochemical reaction in photosensitive materials, transforming them from a ...

View details

HelloPlease log in