UVLED curing machine common terms and units introduced

1257This article introduces common terms and units related to UVLED curing machines, including irradiance, energy density, and wavelength

View detailsSearch the whole station

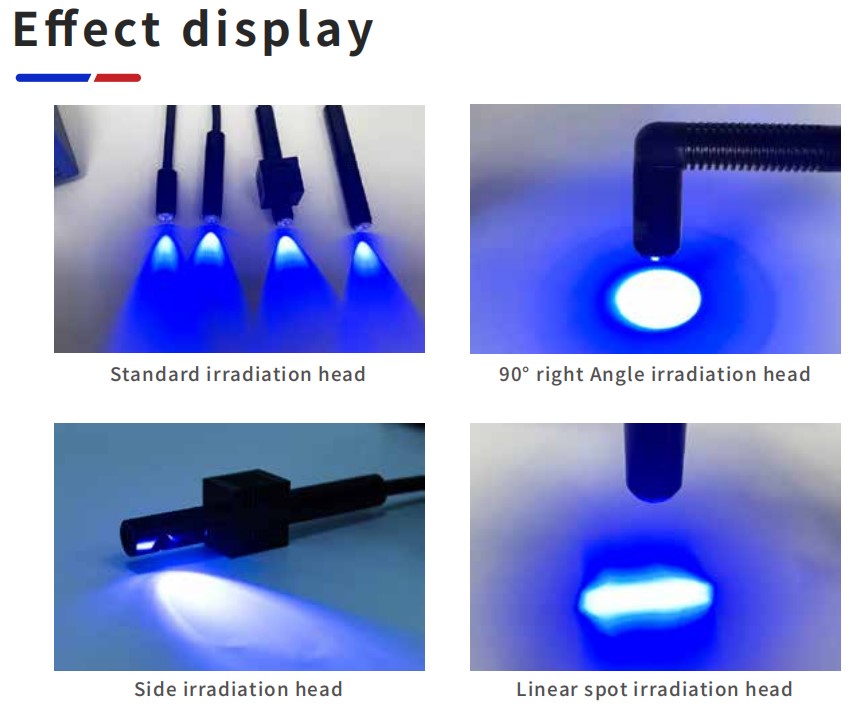

UV LED spot light source is small in size, has strong flexibility, and can be used with multiple irradiation heads according to the demand, especially suitable for optical communication, electronic components, precision instruments, and other industries, compared to UVLED line light source and area light source is popular with users! So how to choose the right UVLED spot light source?

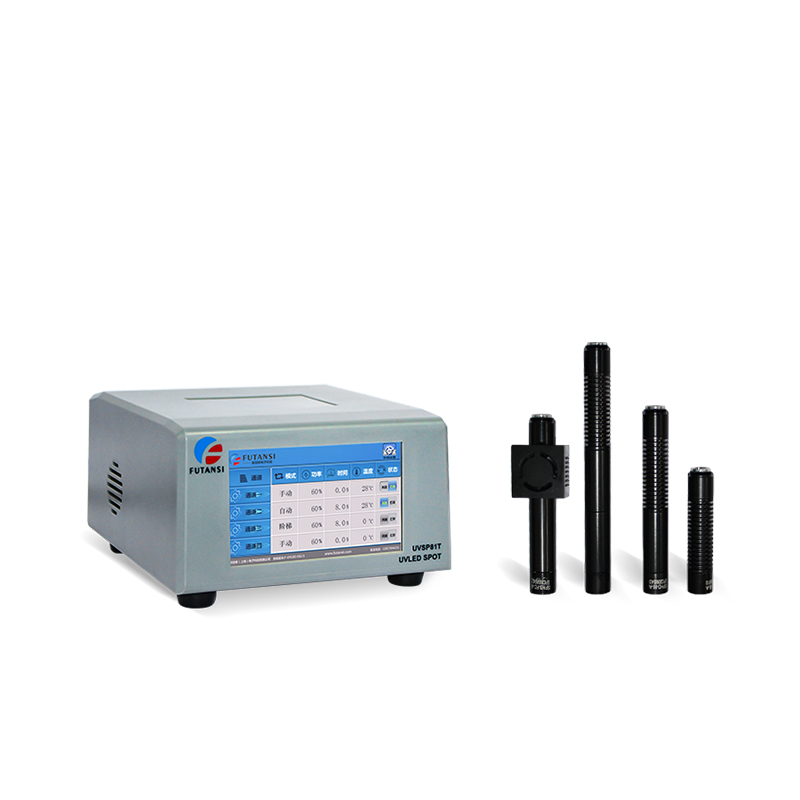

Structure of UV LED spot light equipment

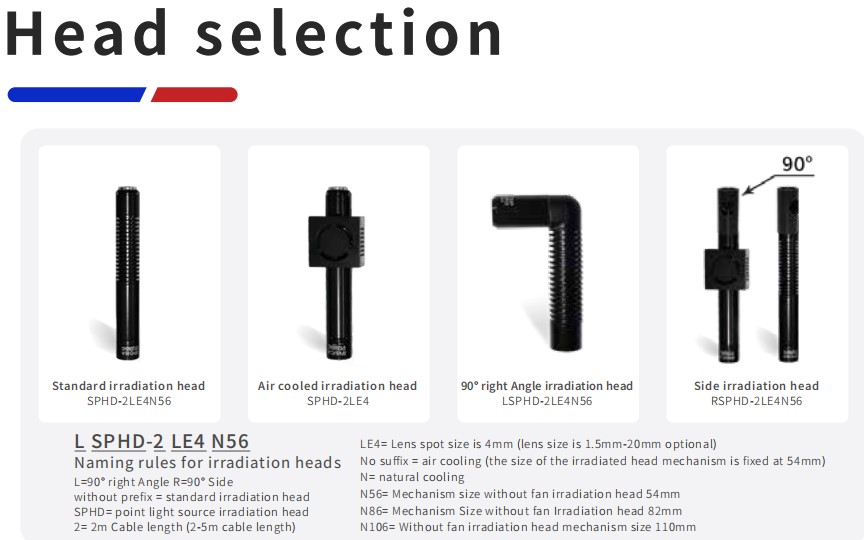

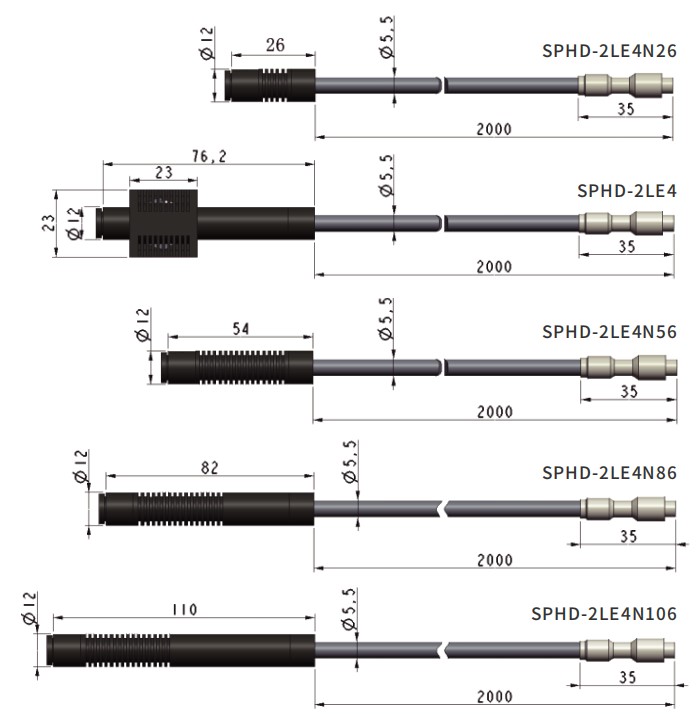

UV LED spot light equipment is mainly composed of the controller, the irradiation head & lens , among which, UVLED spotlight controller is the standard product, irradiation head size is available in four specifications, lens size is available (Ø1.5mm-Ø20mm), heat dissipation mode can be optional air cooling heat dissipation or natural cooling, users can choose according to the requirements of use.

When choosing a UV LED spot light source, you need to consider the following key factors:

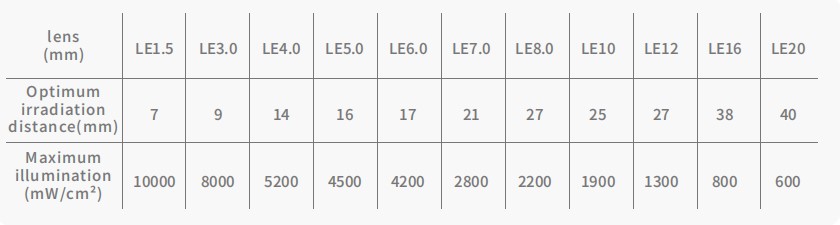

The power and intensity of the UVLED point light source are its most important performance indicators. These two parameters directly affect the efficiency and quality of the UV curing process. Spot UV curing device are available in high power & ultra high power, such as cool cure 365HP & cool cure 405. The image above illustrates the high power light intensity at different lenses.

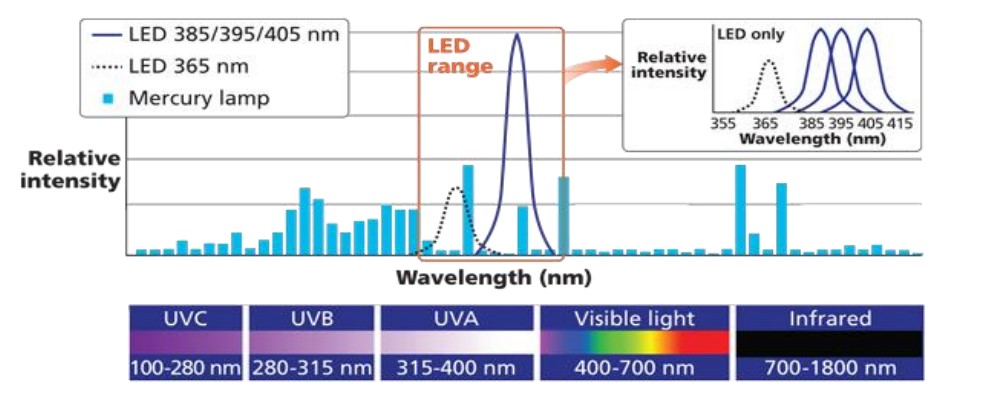

The power and intensity of the UVLED point light source are its most important performance indicators. These two parameters directly affect the efficiency and quality of the UV curing process. Spot UV curing device are available in high power & ultra high power, such as cool cure 365HP & cool cure 405. The image above illustrates the high power light intensity at different lenses. The wavelength of the UV LED point light source should be selected according to the specific application. Different materials have different absorption rates for different UV output. Generally speaking, 365nm, 385nm, 395nm, and 405nm are the most common UVLED wavelength.

The wavelength of the UV LED point light source should be selected according to the specific application. Different materials have different absorption rates for different UV output. Generally speaking, 365nm, 385nm, 395nm, and 405nm are the most common UVLED wavelength.

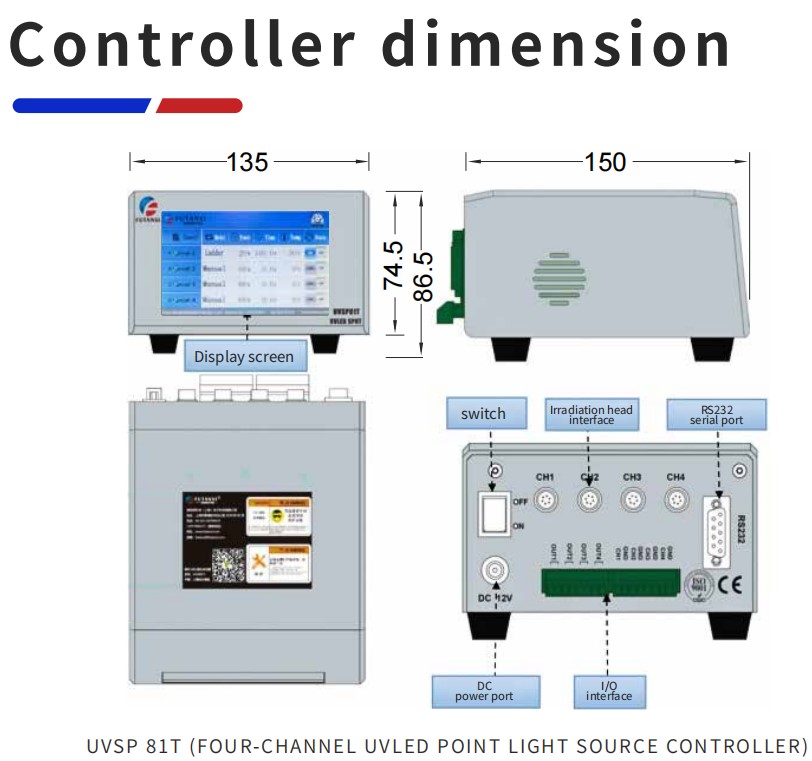

UVLED spot light source control interface should be simple and easy to use so that users can easily adjust the UVLED power, irradiation time, and other parameters. This touchscreen controller above can adjust the light intensity, irradiation time (manual on/off & automatic time off), and operation mode. In addition, the curing light source can be connected to PLC, MODBUS TCP, MODBUS 485, and of course, foot pedal control.

UVLED spot light source control interface should be simple and easy to use so that users can easily adjust the UVLED power, irradiation time, and other parameters. This touchscreen controller above can adjust the light intensity, irradiation time (manual on/off & automatic time off), and operation mode. In addition, the curing light source can be connected to PLC, MODBUS TCP, MODBUS 485, and of course, foot pedal control.In summary, when choosing a UVLED point light source, you need to consider factors such as power, intensity, wavelength, size, shape, heat dissipation performance, control interface, as well as brand and price to ensure that you buy the right product for your needs.

This article introduces common terms and units related to UVLED curing machines, including irradiance, energy density, and wavelength

View detailsDC Probe Station for wafer measurement

View detailsPrecision alignment coupling systems are specialized mechanisms designed to connect two rotating shafts or components with an emphasis on achieving perfect alignment. The primary objective is to ensure that the rotational axes of the coupled compo...

View detailsPrecision alignment coupling systems are specialized mechanisms designed to connect two rotating shafts or components with an emphasis on achieving perfect alignment. The primary objective is to ensure that the rotational axes of the coupled compo...

View details

HelloPlease log in