Precision Alignment Coupling Systems: Enhancing Accuracy in Mechanical Connections

In the realm of mechanical engineering, where precision and accuracy are paramount, the utilization of precision alignment coupling systems has become a cornerstone in achieving seamless and reliable mechanical connections. This article delves into the significance, features, and applications of precision alignment coupling systems, exploring how these systems contribute to enhanced accuracy and efficiency in various industries.

Understanding Precision Alignment Coupling Systems:

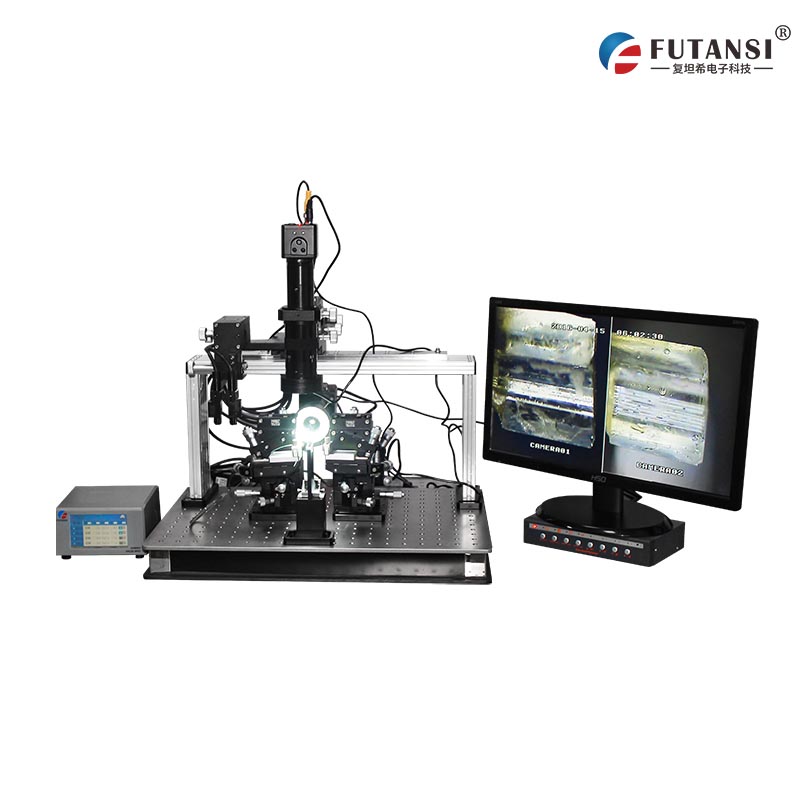

Precision alignment coupling systems are specialized mechanisms designed to connect two rotating shafts or components with an emphasis on achieving perfect alignment. The primary objective is to ensure that the rotational axes of the coupled components are precisely parallel, minimizing misalignment and enabling efficient power transmission. These coupling systems play a crucial role in applications where precision is critical, such as high-precision manufacturing, robotics, aerospace, and medical equipment.

Key Features of Precision Alignment Coupling Systems:

- High Precision Components: Precision alignment coupling systems are equipped with components manufactured to exacting standards. This includes precision-machined shafts, couplings, and alignment mechanisms, ensuring minimal tolerances and high repeatability.

- Flexibility in Misalignment Compensation: These coupling systems often incorporate flexible elements that allow for a certain degree of misalignment without compromising performance. This feature is particularly beneficial in dynamic systems where slight movements or vibrations are unavoidable.

- Zero-Backlash Design: To maintain accuracy and responsiveness, precision alignment coupling systems are designed with minimal or zero backlash. This ensures that there is minimal play or clearance between the connected components, contributing to the precision of the overall system.

- Torque Transmission Efficiency: The efficiency of torque transmission is a critical aspect of precision coupling systems. These systems are engineered to minimize energy losses during power transmission, optimizing the overall efficiency of the connected machinery.

Applications in Various Industries:

- Manufacturing and Robotics: In manufacturing processes that demand high precision, such as CNC machining and automated robotic systems, precision alignment coupling systems play a crucial role. They ensure accurate positioning and synchronization of moving parts.

- Aerospace and Defense: The aerospace industry relies on precision coupling systems for applications like aircraft control systems and satellite mechanisms. The ability to withstand harsh environmental conditions while maintaining precise alignment is essential in these scenarios.

- Medical Equipment: Medical devices and equipment, particularly those used in diagnostic imaging or precision surgeries, benefit from the accuracy provided by precision alignment coupling systems. These systems contribute to the reliability of moving parts in medical machinery.

- Research and Laboratory Equipment: In laboratories and research facilities, where precision is paramount, precision alignment coupling systems are used in various equipment, including spectrometers, centrifuges, and analytical instruments.

Challenges and Considerations:

While precision alignment coupling systems offer remarkable benefits, their design and application require careful consideration. Factors such as environmental conditions, load requirements, and maintenance considerations must be taken into account to ensure optimal performance over time.

In conclusion, precision alignment coupling systems stand as indispensable components in achieving accuracy and efficiency in mechanical connections. As industries continue to push the boundaries of precision engineering, the development and application of advanced coupling systems will remain pivotal in ensuring the reliability and performance of sophisticated machinery across diverse sectors.

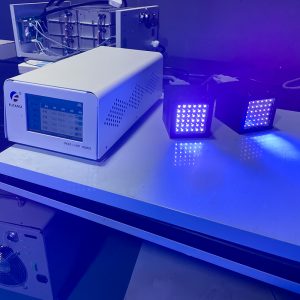

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems

HelloPlease log in